Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

What is a Counting Scale and How Does it Work?

From the receiving room to the stockroom, production, quality control and shipping, counting scales are an essential tool for verifying high volumes of identical parts.

Counting scales are very similar to other scales in terms of weighing, but a counting scale does two additional functions by performing operations in division and multiplication of a single part's weight.

It may sound complicated, but counting scales are actually simple and easy to use.

Why Use a Scale for Counting?

Material Saving

Shipping too many or too few parts means you’re losing money and could also lose a customer. Counting scales can be used to verify the correct number of parts are used every time.

Labor Reduction

Manually counting parts and identifying boxes is inefficient and prone to human error. Counting scales can reduce labor and, with the addition of bar code scanning and labeling, total transaction time.

Inventory Accuracy

Cycle counting improves inventory accuracy, which can also increase productivity and customer service.

Enviornment

Receiving

Accurately verify the count of received goods

Shipping

Shipping

Eliminate under- and over-shipments of products. Find extra parts and assemblies before the customer does.

Production

Production

A precise count of goods sent to the production floor keeps assembly lines moving and on schedule.

Stockroom

Stockroom

Eliminate overage to the production floor and keep items in the stockroom.

Quality Control

Quality Control

Fast cycle counting and package-count checks keep profits in your plant and customers happy.

Best Practices

Make sure the scale is located away from air conditioning vents, as well as drafts from windows or doors.

Use electrical outlets distanced from any machinery or fluorescent lights. Check forklifts in the area to see if they produce static charges. Dissipate this charge before operating the scale.

Use a minimum of 10 samples. Optimize your sample by using the piece-weight enhancement feature of counting scales.

Verify all tare containers are correctly marked for weight, especially if you are not taring at every weighment. Use bar coding to increase productivity.

Sizing a Counting Scale

The internal resolution of the scale must be, at minimum, less than or equal to the weight of one part. The weight of 10 parts should equal 0.1 percent of total capacity. Scale capacity should handle the largest container of the heaviest parts. Use two or three platforms to get this range if needed.

For fast and easy sampling, the sample scale capacity should be no larger than 10,000 times the piece weight. This will allow the sample size to be at least 0.1% of the capacity of the sample scale.

Scale Rental

Renting a scale can be beneficial for companies or individuals who perform periodic inventory counts and do not need to rely on a counting scale for daily business activity. Whether it is monthly, quarterly or yearly, an accurate counting scale maintains best practices for cycle counts.

For example, counting scales will:

- Assist in the accuracy and speed in physical counts of inventory for accounting records

- Provide up-to-date knowledge of stock on hand for production

- Reduce inventory-knowledge loss when there is employee turnover

- For more information on renting a counting scale, please locate a local dealer.

Accuracy

The most misunderstood parameter of a counting scale is accuracy. A number of factors determine counting

accuracy.

- The weighing accuracy of the scale—the scale must be sized correctly for the weighed parts.

- Accuracy of the computed piece weight—this will be determined by the internal count of the scale and

the parts themselves. - Variance of the part—are the weighed parts uniform in size? Machine and material variations result in

different part weights. - Sample size—minimum recommended sample size is 10. Many companies use 100-piece samples or

piece-weight enhancement programs to achieve better accuracy. - Scale operator—errors occur with improper operation of the scale.

- Environment—scales must be placed away from drafts of open windows, doors or heat/air vents.

What is the accuracy of the remote scale?

The unit weight determined on the counting scale is used to determine the count on the larger scale. We can see how this works by applying the elements of the example below. A 5,000-pound counting scale with one million-count resolution divides the 5,000 pounds into 1,000,000 parts. This means that each internal

resolution is translated to 5,000/1,000,000 or 0.005 pounds. However, if you are weighing a large container of light parts, you could introduce an error in a larger floor scale with the internal count reading by 0.005 if the parts weigh less than 0.005 each. If a large number of light parts need to be counted, they can be broken down into 100 or 1,000-piece lots. Each lot will then have a suitable unit weight to be counted on a larger capacity scale.

What is External Resolution?

External resolution, also called display resolution, is displayed in the weight window of the scale. It is calculated by dividing the capacity of the scale by the internal resolution. In most load cell-based counting scales, the external resolution will be one part in 10,000, or 1/10,000. Since calculations in a counting scale are made using internal resolution, external resolution is more important when manually or digitally introducing a tare weight. Less accurate counts result if the value of the tare container is rounded.

What is Internal Resolution?

The internal resolution of a counting scale is the number of divisions into which it divides the total capacity of

the scale.

All weights are calculated on this basis. For example, if some parts were placed on the counting scale, and the internal display showed 12,307 internal counts, the weight to be displayed would be 12,307 times 0.00005 pound = 0.61535 pound. Since the weight display might only be five digits, then the weight display would show as 0.615. This is the external resolution.

The operator then keys in the sample quantity; for example, 15 pieces. The scale still knows how many internal counts are being used (12,307) and now divides this number by 15 to get the number of internal counts per piece: 12,307 / 15 = 820.4666.

The scale has to round off the number to get rid of the decimal, therefore, the scale calls each piece as 820

internal resolution counts. The scale will convert the piece weight into pounds by multiplying the weight per

count times the number of counts: 0.00005 × 820=0.041.

This is displayed in the unit, or piece-weight, window. When the scale detects a change in the weight, it will

complete the calculation in reverse, using the number of internal resolutions per piece as the divisor.

For example, more pieces are placed on the scale and the number of internal resolutions is now 346,712:

346,898 / 820 = 423.04, rounded to 423 pieces.

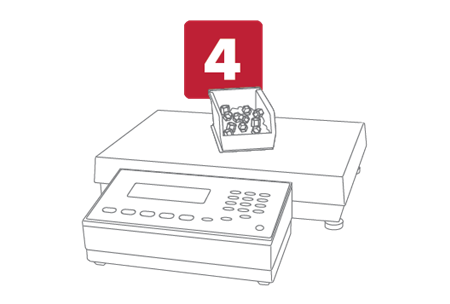

Sample Operation of a Counting Scale

Sample Size

A sample size gives counting scales the information needed to count accurately.

A sample size gives counting scales the information needed to count accurately.

By placing as few as 10 identical parts on the scale, a counting scale can determine how much a single part weighs (average piece weight) and apply that calculation to larger loads to determine an accurate parts count.

The larger the sample size used, however, the better average piece weight is obtained. Many companies use 25, 50 or 100 units per sample to achieve the best accuracy. We recommend sampling 100 pieces to achieve the best accuracy; however, a larger sample quantity also introduces an element of human error.

Ten groups of 10 should be counted out by hand, then placed on the scale as a 100-piece sample. Here are some questions to ask yourself when determining a sample size:

- Is a 10-piece sample sufficient weight on the platform?

The sample should be at minimum 0.1% of the total capacity. - How uniform are the parts being weighed?

A larger sample size provides sufficient data to determine the most accurate unit weight. The piece-weight enhancement feature of the DIGI scales assists in sampling larger sizes accurately.

Average Piece Weight Versus Weight Per Thousand

What is the difference between Average Piece Weight and unit Weight per Thousand?

A penny weighs 0.005 pound; this would be the average piece weight. However, if we were to display this as unit weight/1,000 we would discover that the penny actually weighed 5.94 unit weight/1,000 (or 0.00594 if displayed as an average piece weight).

If the average piece weight display is limited to five digits, then the unit weight per 1,000 allows the significant digits to be entered without being “crowded out” with the leading zeroes. Ultimately, the lighter the part, the more it affects the count accuracy.

What does this mean to you? Compare the math.

10 pounds of pennies on the scale – 5.10/0.005 = 1020 pennies

10 pounds of pennies on the scale – 5.10/0.00594 = 858 pennies

See the difference in count?

Unit weight per thousand allows a more accurate count.

Request a Demo or Dealer

Counting scales are an essential tool for counting high volumes of identical parts. Rice Lake has a selection of reliable and user-friendly scales you can count on for your specific application needs. To request a demo or quote from an authorized Rice Lake distributor, complete the form below.

My Account

My Account