Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set to the United States. Please confirm or select a different region.

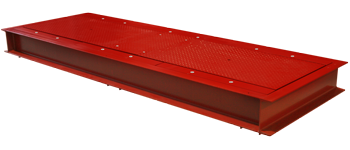

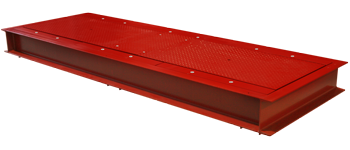

Flush-Floor Platform for Axle Weighing Stations

- Designed for controlled-access weighing stations, with vehicle transit at reduced speed within 5km/h (refer to installation manual for more information)

- Accuracy 1% for internal use, 2% for legal for trade use. These accuracies can be obtained by following the installation specifications and instructions in the installation manual.

- Anti-slipping loading surface made of sheet metal, sized to withstand any load on the basis of the parameters dictated by the Directive 96/53/EC (maximum load on single axle for vehicles transiting in Europe).

- Steel beam supporting structure.

- Sized to weigh axles up to 20t and detect axle overloads up to 30t (refer to product manual for use and maintenance conditions).

- Complete with frame for the containment, made up of a single bearing structure, in welded painted steel, that does not require assembly. It facilitates the installation of the scale and simplifies the masonry.

- Sandblasting and varnishing with bi-component epoxy coating, highly resistant to corrosion.

- Dimensions of the load surface (lxw): 3 x 0.73 m.

- 6 compression load cells, class C3, stainless steel, with IP68 protection.

- 20m cable for connection to the weight indicator.

- Dust and waterproof wirings and connections, easy to connect and disconnect.

- Hermetic junction box.

- Central inspected trapdoors for the ordinary maintenance.

- Wide range of connectable weight indicators, also functioning with rechargeable battery, which allow to use the platform also without an electrical power supply.

RWS is an axle weighing platform designed to build weighing stations for checking the axle weight of vehicles. RWS also makes it possible to calculate the weight of a vehicle in transit by summing the various axles, weighed while stationary or in motion.

RWS is CE approved according to Directive 2014/31/EU for verification of the axle weight.

Flush-Floor Platform for Axle Weighing Stations

|

Main applications:

|

Stationary and In-Motion Weighing: Depending on the combined weight indicator, the axles of the vehicle can be weighed while stationary or in motion: - The stationary weighing function allows the vehicle to be weighed by adding up the weights of the individual axles. |

Certifications and Approvals:

|

Available versions

Code |

l x w x h (mm) |

Nr. of cells | Max (kg) |

d (kg) |

|---|---|---|---|---|

| RWS | 3000x730 | 6 x 12500kg | 30.000 (•) | 20 |

(•) Sized to weigh axles up to 20t and detect axle overloads up to 30t (refer to product manual for use and maintenance conditions).

WARNING: the product requires special transport, with quote.

Application scheme for flush floor installation

Parts

| Part # | Description | List Price | Cart | |

|---|---|---|---|---|

|

RWS | Platform for weighing axles up to 30.000kg, resolution 20kg. Lobed sheet metal platform 3 x 0,73m. Complete with containment frame. For applications in private areas/company entrances/logistics hubs with vehicle flow limited to weighing operations and controlled speed in and out of the weighing area, not exceeding 5km/h. |

Call for price |

Options

Available versions

| Part # | Description | List Price | Cart | |

|---|---|---|---|---|

|

RWS | Platform for weighing axles up to 30.000kg, resolution 20kg. Lobed sheet metal platform 3 x 0,73m. Complete with containment frame. For applications in private areas/company entrances/logistics hubs with vehicle flow limited to weighing operations and controlled speed in and out of the weighing area, not exceeding 5km/h. |

Call for price |

Legal for trade approval (only at time of order)

Calibration service with weight indicator

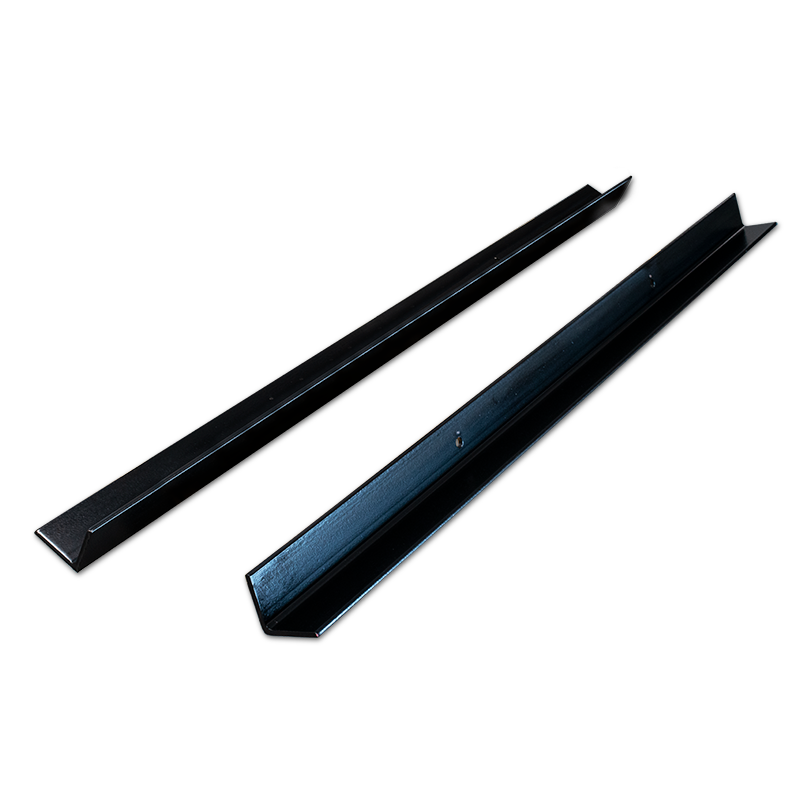

Bars for facilitated installation

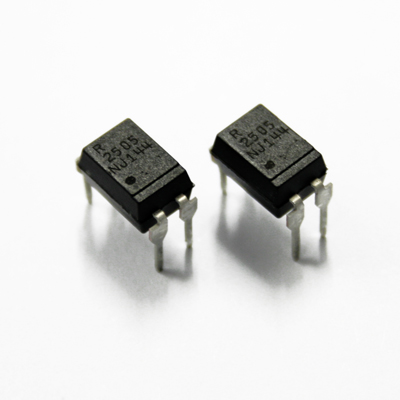

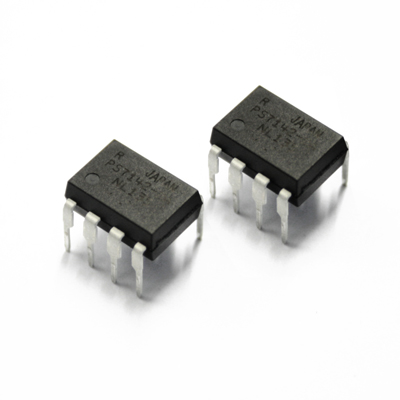

Protection for junction box/electronic circuits

3590E weight indicator in "AF09" version, OIML R134 certified

Communication Interfaces

Storing the weighs (only at time of order)

Calibration service with Dini Argeo indicator (only at time of order)

Accessories for post-installation finishing

Related Products

3590EGTBOX8 Kiosk with Weight Indicator for Self-Service Systems and Weighbridges with 8" Touch-Screen

Stainless steel kiosk with 8" touchscreen weight indicator, perfect for self-service weighbridges management. Fitted with thermal printer and RFID reader or coin acceptor. Open to CE-M type-approval.

3590EGT8 8 inches Touch Screen Weight Indicator

Weight indicator with 8-inch touchscreen display. New IP68 housing with adjustable viewing angle brackets. Integrated LED control light on the front panel and Integrated Ethernet port as standard.

3590EGT Graphic Touch Screen Weight Indicator for Industrial Applications

Digital weight indicator with touch screen display, suitable for advanced industrial applications. Visualize weighing data and customize screens to simplify the user operations.

3590ET Touch: Touch-Screen Weight Indicator for Industrial Applications

Digital weight indicator with a big touch screen display, suitable for advanced industrial applications. It allows the visualization of all the weighing data and the customization of the screens, simplifying the user operations. Fitted with 3 serial ports, transmission protocols for data communication, completely configurable printouts, integrated alibi memory, and port for connection to barcode/badge reader. CE-M approvable (OIML R-76 / EN 45501).

AF09 Software for 3590E/CPWE Indicators For Axle Weighing

Software suitable for advanced applications of axle weighing and totalization for control of the weight of the vehicle or for input / output weighing.