Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set to Italy. Please confirm or select a different region.

How to Choose the Best Load Cell for Your Needs

Load cells represent the heart of any weighing system.

Although often invisible to the human eye because they are enclosed in scales, they are present in many everyday objects.

To understand how widely load cells are used, you should think of electronic scales, bottling or can-filling equipment, drug-packaging machines, bagging machines, and filling machines, as well as applications in the automotive, logistics, aerospace, chemical, and agri-food industries.

Load cells are generally constructed of steel or aluminum and one or more strain gauge with a Wheatstone bridge circuit. These high-precision electronic circuits are carefully placed in the load cell and protected from external damage. As weight is applied to the load cell, it bends slightly, causing the electrical current in the strain gauge to change. Modern digital weight indicators are able to process these electrical variations and determine the weight applied.

Only quality load cells can ensure consistently accurate readings precisely because of the use of highly reliable and repeatable strain gauges and materials.

Choosing the right load cell for your needs depends on several key factors. Here are some elements to consider:

- Environment: It is critical to choose a load cell that is suitable for the environment in which it will be placed. Environmental conditions, such as temperature, humidity, corrosion, and vibration, can affect the performance of the load cell.

- Capacity: Defining the load range you plan to measure is very important to ensure that you choose a load cell that can cover it without exceeding it or being extremely underloaded. It is preferable to choose a load cell with a slightly higher capacity than you expect to need, so the system is protected from any unexpected overloads or variations.

- Precision and Accuracy: Assessing the precision required for measurements is important. Load cells vary in the levels of accuracy offered. If extremely precise measurements are required, it will be wise to select a load cell with high accuracy specifications.

- Type of Load: there are different configurations of load cells designed to measure tensile, compressive or shear loads. Make sure the load cell is suitable for the type of force to be measured.

- Approvals: If load cells are used for measurements that affect trade, such as weighing goods for sales or taxation, the application requires the use of OIML R60 approved load cells.

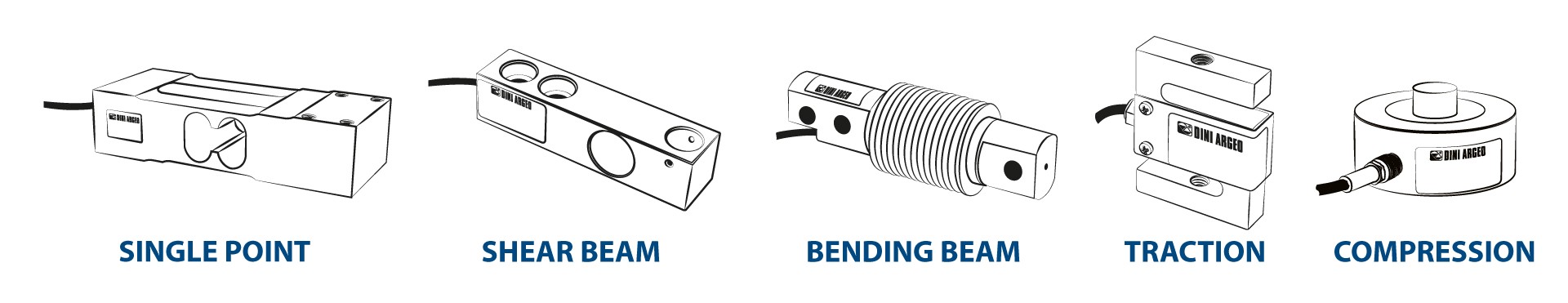

5 Main Load Cell Types

There are as many types of load cells as there are applications that use them. Here are five common types of load cells and their typical uses.

Single point load cells: Ideal for weighing at every point on the platform.

- bench scales, floor platforms, fast weighing systems -

Shear beam load cells: Perfect for achieving accurate weighing by applying force at a specific point.

- medium-capacity silos and hoppers, floor platforms -

Bending beam load cells: Excellent combination of the responsiveness and accuracy of single point load cells with the strength of shear beams.

- roller conveyors, floor platforms, silos, hoppers and small capacity tanks -

Traction load cells: These measure weight when force is exerted in tension or compression, making them ideal for converting suspended vessels into weighing systems.

- hoppers and suspended loads -

Compression load cells: With a compact and robust shape, they are designed to weigh without mechanical bending, making them very durable and resistant to extreme stress.

- silos, hoppers and tanks of medium and large capacities -

Certifications

The type of load cell certifications depend on what they weigh and their function. Some of the most important certifications are:

Metrological Approval

OIML: Approval for equipment used with third parties (internationally).

NTEP: Approval for equipment used with third parties (U.S. market specific).

Explosion Hazard Certifications

ATEX: Approval for equipment suitable for installation in explosive environments.

FM Approved: Approval for property loss prevention and safety equipment in commercial or industrial facilities.

FM Approved cUS: Approval for equipment that meets the requirements of FM Approvals and the Standards Council of Canada.

Dini Argeo can also design and manufacture custom load cells, consult our sales department for more information.

Dini Argeo, an Italian company of the international Rice Lake Weighing Systems group, specializes in the production of scales and weighing systems. Thanks to more than 100 years of experience in weighing, logistics and industrial automation, Dini Argeo offers its customers around the world quality, guaranteed and certified weighing solutions at competitive prices.