Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set to Italy. Please confirm or select a different region.

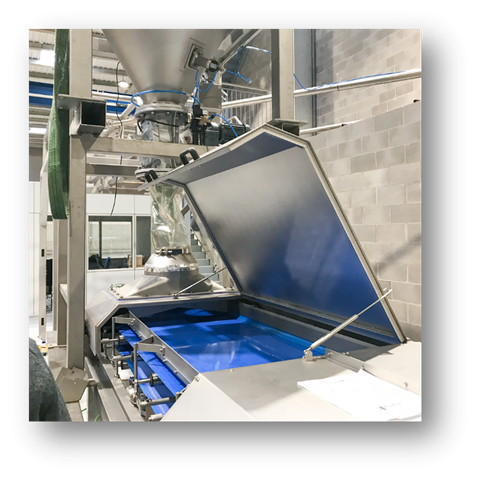

Incorporate More Control with Weigh Belt Feeders

All weigh belt feeders are unique and designed according to each individual application. The following case study examines the use and ROI of a Master™ weigh belt feeder for an application in South America.

Automating Flour in South America

A company that specializes in automating the handling and processing of flour in Colombia needed an in-motion bulk weigh belt feeder approved for use in potentially explosive environments.

Since flour dust is a high risk when it collects into a combustible cloud, this system needed to be approved for ATEX Zone 22 dust zones.

The Master weigh belt feeder was the best choice for the application. Not only does the weight belt meet the ATEX Zone 22 requirements, but it maintains a consistent flow of material.

Standard or Customized Weigh Belt Feeders

Weigh belt feeders are ideal for a wide variety of industries including food, mining, process control and bilk material blending. Control the flow of product with a Master weigh belt feeder to ensure accurate and consistent weight output.

Weigh belts and weigh belt feeders can be customized to customer specifications.

Dini Argeo, an Italian company of the international Rice Lake Weighing Systems group, specializes in the production of scales and weighing systems. Thanks to more than 100 years of experience in weighing, logistics and industrial automation, Dini Argeo offers its customers around the world quality, guaranteed and certified weighing solutions at competitive prices.

My Account

My Account