Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

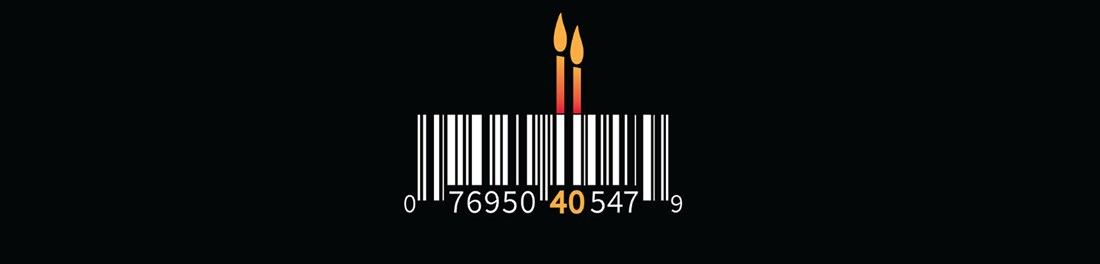

40 Years of Bar Codes

In 1974, a transformation began. The first bar code was scanned on a pack of Wrigley’s® chewing gum and the world of retail was forever changed.

Forty years later, the bar code’s ruby anniversary is being celebrated for its automation contribution and widespread use. In fact, rarely is a product sold today without using one.

Publish Date: 04/15/2015

The Bar Code's Origins

The invention of the bar code is most widely credited to Norman Joseph Woodland who developed the idea in the late 1940s. Woodland wanted to streamline processes at supermarkets and invent an automated method to capture product information at checkout. He developed the bar code system, which converts Morse code into a linear, two-dimensional system, by representing the code’s dots with thin bar lines and its dashes with thick bar lines. Although bar code structures have changed since then, its basic functionality remains the same.

While almost everyone has used a bar code in one way or another, few understand how it actually works. Retail Universal Product Code (UPC) bar codes consist of a minimum of two sections of scannable information. The sections are divided by three sets of slightly longer lines. These sets of long lines do not interpret numbers, but are used to help the scanner read the entire bar code. The first section of short lines represents the numbers listed below the section, which correspond to the retail company or manufacturer of the product. The second section of short lines represents the numbers that correspond to the product’s identification code or other product information, such as price or weight. In the above bar code, the first section of short lines represents 76950, which identifies the company selling the product. The second section of short lines represents 40547, which identifies the product. The last piece of code, represented in this bar code with the number 9, is the check digit. The check digit is a direct mathematical sum when all of the previous numbers are entered into a checking formula. The purpose of the check digit is to verify the entire bar code is correct and without errors.

The entire sequence of code creates a unique part number for the company and product. When bar codes were first introduced, there were more than enough unique codes for each company. Since then, however, commerce has expanded and the number of companies using UPC has skyrocketed. Soon, the UPC will have exhausted all available company prefixes, prompting the bar code to evolve in order to overcome its limitations.

As of January 1st, 2005, all North American retailers should have expanded their UPC data structure capabilities through the Sunrise 2005 initiative to process 13-digit field lengths, including EAN-13 symbols. Furthermore, Global Standards (GS1) recommended database expansions to accept 14-digit data structures, which will support the Global Trade Item Number (GTIN) for efficient and seamless global trade.

Parts of a Bar Code

Understanding how bar codes are organized and function can help increase our usability of them for many applications and industries.

Beyond the Supermarket

Throughout its 40 years, bar codes quickly expanded into manufacturing, pharmaceutical and practically every other industry. Certain bar codes, such as Code 39 and Code 128, have become standards, providing general functionality that can be applied to multiple industries. Code 39 is a variable length bar code, consisting of uppercase letters (A through Z), numeric digits (0 through 9) and a number of special characters.

Code 128 is also a popular bar code. It provides verification protection with a checksum digit and byte parity checking and is commonly used in shipping and packaging. Widely used to encode relatively large amounts of data in a small amount of space, Code 128 was designed to encode all 128 ASCII characters.

Bar Codes in the Weighing Industry

Counting scales often have the capability to add a scanner to read bar code information and are set up with headers to identify data in the code. The scanned data could be a product identification code, tare weight or unit weight. This information automates processes, speeds up data entry and improves accuracy and efficiency.

General bar code commands include: soft key presses, tare, enter, zero, change from gross to net, and entering additional information. Any data that can be sent to a scale by RS-232 can be sent by scanning, rather than manual button-pushes. The commands and processes available are extensive, yet are dependent on the type and capabilities of the indicator used for the application.

The KUNITS command in most Rice Lake Weighing Systems indicators will toggle between units of measure. By scanning this command, operators could change from pounds to kilograms by a scan, saving steps for the operator and improving process time.

The KPRINT command initiates a Print key press. The operator performs the command by using a bar code scanner in their work station after loading product on the scale. The use of the scanner saves steps, minimizes operator movement, and Identifies the manufacturer or retailer selling the product Identifies the product, or product information such as price or weight Code 39 - Variable length bar code Code 128 - Commonly used in shipping and packaging for verification protection reduces equipment wear by eliminating multiple key presses.

Eliminate Errors and Initiate Functions

In precision industries like pharmaceuticals, exact measurements and eliminating errors are essential to accurate weighing processes. When applications require multiple measurements on concurrent scales, human data entry error is possible. Scanning bar codes to initiate functions helps eliminate those errors. By using bar codes, the operator can easily scan tare weights, change from gross to net, enter measurements, toggle between units of measurement or even change which scale is being used.

The applications for bar codes are constantly developing and will continue to help streamline processes in the future. No matter the industry or application, throughout its 40 years, the bar code has helped eliminate manual data errors, improved processes and reduced operation steps, providing more than enough reason to celebrate this automation pioneer.

My Account

My Account