Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

5 Things to Consider When Purchasing a Floor Scale

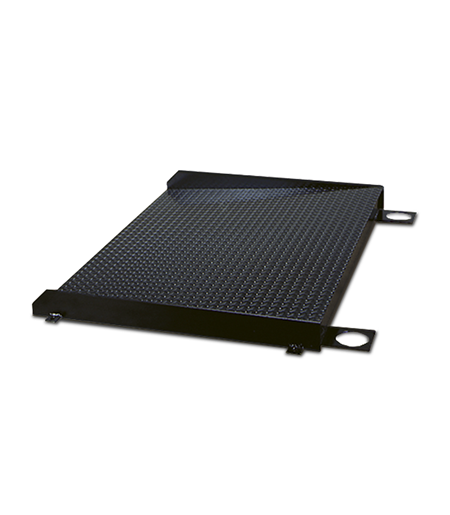

Many types of floor scales are available to meet the requirements of every job. Each type of floor scale has its own distinct benefits, whether it is pit-mounted level with the floor, has aboveground access or is paired with ramps.

What to Consider When Purchasing a Floor Scale

Before purchasing, it is important to consider the scale’s planned location, how products are loaded, cleanout options, what items are being weighed and whether you should work with a qualified scale dealer to ensure your requirements and future support needs are met. Use this guide to help choose the right scale for your application.

1. Floor Scale Location

What is the traffic like around your scale? If it is mostly foot traffic from employees, an aboveground floor scale could present a trip hazard, so you may want to consider pit-mounting your floor scale to help eliminate hazards. If traffic is mostly from forklifts, you should consider the potential for a forklift to accidentally drive over a pit-mounted floor scale. This could cause damage if the forklift exceeds the floor scale’s capacity, which would negatively impact the accuracy of future weighments if not repaired. As you’re considering the traffic that will surround your floor scale, you should also think about the footprint of your equipment. How much space will it require at your facility? When you choose the location of your floor scale, ensure there is enough space to safely load and unload products from the weighing platform.

2. How Products Are Loaded

You may need to consider including ramps or bumper guards with your floor scale system, depending on how you choose to load or unload products. If products are in carts or bins, a pit-mounted floor scale may be the best option, as it allows you to easily roll containers onto the weighing platform. When using a forklift to load products onto the platform of an aboveground floor scale, you should consider installing bumper guards on the sides of your floor scale facing forklift traffic. Bumper guards are bolted to the floor around your scale to protect it from contact with a forklift or other potentially damaging traffic. They are also typically painted “safety yellow” to be highly visible to forklift drivers. If you plan to use a pallet jack to load products onto your aboveground floor scale, you will need to consider the length of ramps leading up to your scale. Depending on the length of tines on your pallet jack, you may need to increase the ramp length. Make sure ramps can accommodate the space needed for tines to be removed without catching under your products.

3. Floor Scale Cleanout

Another aspect to consider when deciding between a pit-mounted or aboveground floor scale is the cleanout. Dirt and debris can accumulate under your scale throughout day-to-day processes, which can negatively impact the accuracy of your scale. If the build-up lodges debris between the weighing platform and frame, or around the load cells, your scale may not be able to provide accurate weighments. An aboveground floor scale allows for easy cleanout beneath the scale while a pit-mounted floor scale can be more challenging. If your floor scale does not have a hinged top plate, the entire scale will need to be lifted out of the pit for cleanout. Luckily, there are floor scales designed to be pit-mounted with hinged tops to make cleaning fast and effective.

4. What Is Being Weighed

Think about what you are weighing when you consider the size, capacity, style and material you need for your floor scale. If you have a highly sanitary environment, you will need a stainless steel floor scale. If not, a painted mild steel floor scale should meet your requirements. If you have non-standard size or space requirements, be sure to work with a manufacturer who can create a customized floor scale that meets your specific application needs.

5. Working with Qualified Dealers

One of the final things to consider when purchasing a floor scale is whether you will work with a qualified scale dealer. By working with a scale dealer, you have the confidence of knowing your scale will be installed by knowledgeable, experienced professionals, ensuring your system is operating properly. Choosing to work with a scale dealer also gives you the benefits of a local, experienced scale specialist for maintenance and support. Rice Lake Weighing Systems’ line of RoughDeck® floor scales are available in any size, shape and capacity, meeting the needs of even the most demanding applications. Rice Lake works with a large dealer network to ensure you have experienced support available on-site when you need it most. Whether you need painted mild or stainless steel, ramps or bumper guards, aboveground, pit-mounted or even a portable floor scale, there’s a RoughDeck to fit your application.

My Account

My Account