Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

Efficient Chemical Batching

Adhesive, beauty care, laundry and home cleaning product batching recipes must be carried out precisely to ensure product quality. When a leading consumer goods manufacturer needed to optimize batching for their products, they trusted a Myrias® software system.

The Challenge

Consumer goods manufacturers are held to high standards. Not only must their products be safe for use, but customers expect them to perform the same way with every purchase. Customers need to know the adhesive will stick and laundry detergent will clean clothes without damaging them, which means manufacturers must exactly replicate the recipe every time they batch a product.

Consistency and accuracy build customer loyalty, but optimizing ingredient use can also reduce expenses for manufacturers. For one international company, this meant upgrading their chemical batching processes to ensure batches could be manually adjusted based on quality assurance feedback. They needed to be able to select previous batches and add additional ingredients before sending the batch back to quality assurance. Because they are batching more than one order at a time, they also need to be able to select one ingredient to be used in multiple orders simultaneously.

The Solution

By working with their local scale dealer and Rice Lake Weighing Systems’ software team, the consumer goods company updated their batching process to keep up with demand.

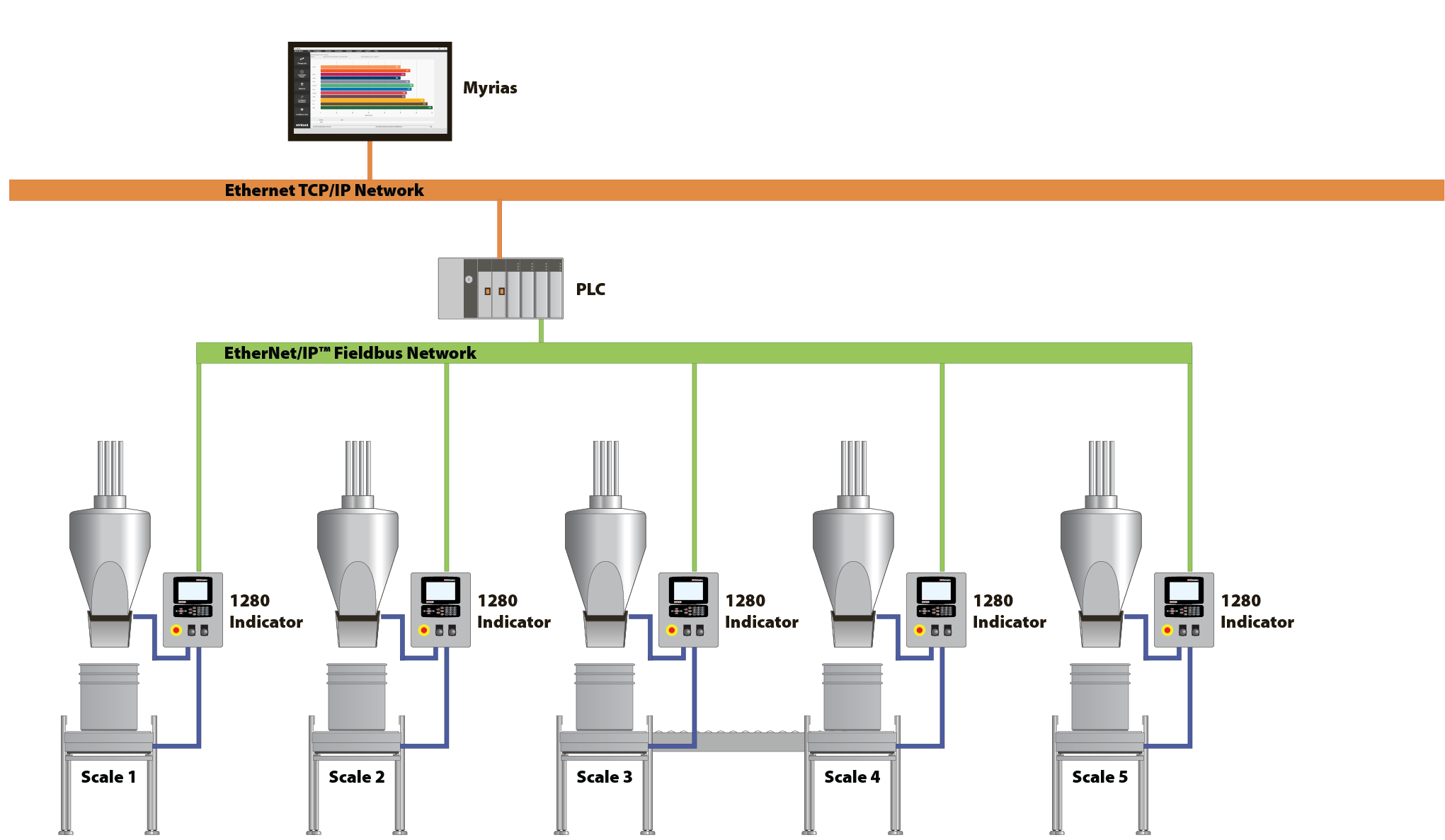

The company chose to use the Myrias recipe batching module on five 1280 Enterprise® Series weight indicators. Production operators at each terminal initiate mixing for batches to fulfil an order, then send the batch to quality assurance (QA). If the QA team requests ingredient additions to bring the batch within specifications, production operators are able to select the previous batch from the Myrias menu and make adjustments before sending it back to the QA team for approval.

This system also supports concurrent batches, allowing a single ingredient to be measured for multiple batches at the same time, improving efficiency and material management. Myrias batching software also provides traceability to help the company maintain compliance with product record requirements.

The company chose to initially implement Myrias at one facility to understand how it could benefit their operations. Because Myrias is a scalable system, they are able to seamlessly expand their use of Myrias to additional manufacturing facilities as the need arises.

Subscribe to Rice Lake Magazine

Sign in or create a Rice Lake website account to request a Rice Lake Magazine filled with application stories like this one be sent to you.

Account Sign In Create an Account

My Account

My Account