Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

From the Heart of Darkness, the BCi Brings Energy

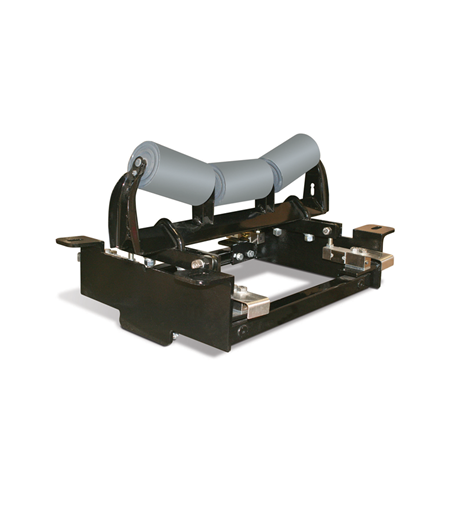

The BCi scale/920i indicator combo is used throughout the lifecycle of coal, from the mine, to barge loading, to its final destination at the power plant.

Caleb Olson and Hannah Martell, technical writer and graphic design specialist for Rice Lake Weighing Systems, respectively, visited Kaskaskia Valley Scale Co., southeast of St. Louis, MO. The following is a recollection of their experience.

There are many automobiles that strike the fancy of the male spirit. As I waited at the Budget Rental car station in St. Louis, MO., I wondered which of these amazing chariots the kind professionals behind the counter would select for us. Eyeing us down, I was certain they had correctly estimated our impressive style and would make a choice worthy of our emanating desire.

“Mr. Olson, your car is ready,” I heard in a slight southern drawl.

I hopped to my feet, snatched the keys, signed a form I will never understand, and Hannah and I rushed outside, wondering whether the Dodge Viper or Corvette was eagerly awaiting its new masters. We loaded our equipment in the back, climbed in, and turned the key of our Hyundai Santa Fe. Unsure if it was actually running, to be a small part of their continued success.

I moved the shifter into “D” and gave it some gas, leaving the Budget Rental car station. Now on the highway, I had become 80% sure it was running, despite lack of audible confirmation.

Hannah and I were in the St. Louis area on a mission to capture video and still footage of Rice Lake’s BCi In-Motion Belt Scale System. With a combined three years of experience in the scale industry, and both of us spending the majority of our days in front of a computer (as a technical writer, I primarily write manuals; as a graphic design specialist, Hannah spends most of her time photo and video editing) it would also be an adventure into the “real world.” We were anxious to see in exactly which applications the BCi was being used.

Finding ourselves moderately disoriented in an unfamiliar city, we were lucky to have Todd Dietrich, of Kaskaskia Valley Scale Co. to show us the way. We joined Todd, whose specialty is in-motion checkweighing, and made our way to our first stop—Peavey Dock, just outside of St. Louis. Here we observed Rice Lake’s BCi delivering fertilizer to barges on the Mississippi River. The fertilizer raced its way across the belt and, like a mutant waterfall, dropped a white river of pellets into each barge container. Today was to be our fertilizer and aggregate day (the following days would be consumed by coal). We loaded our equipment and traveled to Granite City Terminal in Granite City, IL.

Here, Hannah and I witnessed the BCi again drenched in fertilizer, only this time it was loading trucks—lots of trucks. In fact, there were so many that a traffic jam of awaiting truckers monopolized the nearby service road; each eagerly inching their way toward the facility’s entrance when the first in line was allowed to enter. The busy terminal was utilizing a wheel loader to dump ammonium nitrate fertilizer through a floor grate, landing on a high-speed belt.

From here, the fertilizer elevated through a covered conveyor until it reached the end of its relatively short line, positioned directly above a truck. In a matter of minutes, the truck was completely full and made its way to the facilities exit. Granite City Terminal reminded me of a busy restaurant and I imagined the excitement of the next trucker in line when notified he could enter. It was akin to waiting for a table and being overjoyed, thinking “Ooh, I’m next!” when seeing someone had just finished.

Now racing against the setting sun, we made our final stop of the day at Beelman Truck Co., also in Granite City. One look at the facility and it was clear that Beelman specializes in aggregate. A perfectly timed coordination of crisscrossing trucks and wheel loaders navigated the large quarry. In the distance, a mountain of blast furnace slag was being air-cooled. It looked like remnants of a volcanic eruption, emitting steam as a nearby wheel loader carefully did its work. Bill Emmendorfer, plant manager, escorted us to a bird’s-eye view of the facility. From our perch, we could see an intricate highway of conveyors leading aggregate over the BCi. The sun now dipping below the horizon, Hannah and I made our way back to the hotel.

After a solid night’s sleep, the next morning we met Todd at his office in Lenzburg, IL. From there, we traveled to Peabody Gateway Coal, near Coulterville, IL. According to Peabody Energy, the mine shipped 2.4 million tons of coal in 2006. Most of the coal is supplied to Northern Indiana Power Service Company, Tampa Electric and Archer Daniels Midland. The mine has 20 million tons of recoverable coal reserves, 230 employees, and operates seven days a week, year-round. The coal travels from the mine via a 1,200-foot beltline to temporary storage and then travels by overland belt 1.4 miles to the preparation plant.

Toward the beginning of that 1,200-foot beltline is where Rice Lake’s equipment comes in to play. This sounded pretty interesting to me, and I was excited to see the mine. Neither Hannah nor I had ever been in a coal mine before. (First, however, we had to be informed of the various ways we may be killed during our suddenly more ominous visit.) After watching an instructional video on how to use the respirator we would soon be wearing and learning other safety procedures, we fully clad ourselves in mining attire, complete with a hard hat/head lamp combination, safety goggles, respirator, and what felt like a 10-lb battery hanging off our pants. It is believed British sailors invented the belt buckle in the 1600s. I thanked them.

Todd “Ring” Leverton, belt line engineer at the mine and referred to as “Ring” because he sports an earring in one ear, joined Todd Dietrich, Hannah, and me as we made our gradual descent via service elevator. Two hundred feet later, the dark mine waited for us. We flipped on our head lamps, and quickly learned not to look each other in the eye. The head lamps were like looking into the sun on a foggy morning, except the fog was actually coal dust.

I looked around. The scenery looked like a post-apocalyptic world—devoid of sunlight; strange-looking vehicles; everyone wearing protective gear and covered in dust; and catacombs as far as the eye could see. The only thing missing was murderous robots.

Hannah and I loaded the camera gear in one of those odd-looking vehicles, a cross between a miniature Humvee and an oversized golf cart. “Ring” manned the helm and we were on our way. Periodically, I would catch a glimpse through an adjacent tunnel and see the massive conveyor. After a series of turns onto underground roads that all looked the same to me, we finally stopped at a dimly lit area of the conveyor. A 920i, covered in coal dust, was mounted to a nearby wall. Beneath it ran a never-ending river of coal, rapidly traveling to escape the mine while the 920i dutifully displayed the belt speed, current load and rate per hour.

Todd mentioned, “You see those cables running along the ceiling through these tunnels?” We nodded.

“In case something goes wrong, that’s there so the miners can find their way out. There are little arrowheads on the cable pointing toward the exit.”

I didn’t remember that from the video. What other crucial information had I missed? I formed my own escape plan.

I was certain I could just hop on the conveyor in case of emergency. Actually, I wondered if I could hop on the conveyor just for fun. It would be like a reverse waterslide, I thought.

After capturing enough footage, we made our way out of the mine. Without “Ring” driving, Hannah and I would likely still be down there. It amazed me how he could navigate the identical tunnels as if there was a secret system of street signs not told to outsiders.

After exiting the mine, we traveled to Kinder Morgan, Cora Terminal Facility in Rockwood, IL. This terminal receives coal via railway, uses a larger-than-life machine to tip rail cars upside down to retrieve the coal, and transports the coal via conveyor to awaiting Mississippi River barges. Again, we were surrounded by a river of coal quickly navigating through a long, bending belt system until it reached its desired position and was dumped into a barge. Due to the massive Mississippi River current, a small tugboat was constantly pushing against the barge to hold it in place. Like Peavey Dock, there was even a waiting line here. The coal seemed to endlessly dump into each container, and the sun was beginning to set on another day.

The next morning, I blew my nose to find a coal-dust-ridden tissue in my hand. Like the soreness your body feels the morning after a hard day’s work, Gateway Mine did not let me forget where I was the day before. But today was a new day.With one day and one stop left, the next morning Todd, Hannah and I loaded up the Hyundai and left on a 500-mile round trip visit to Duke Energy Cayuga Station, on the shores of the Wabash River in Cayuga, IN. This 1100-megawatt power plant utilizes a twin-920i setup with matching BCi scales to accurately monitor its coal use. In addition, the 920i outputs a serial audit trail of weight, time and date. Alternatively, it can send an analog output to a chart recorder or communicate to a Programmable Logic Controller with a protocol card. Bob Cooper led us around the plant, currently expanding its size.

He commented that in his industry, it is of the utmost importance to maintain accuracy. Overcharging a customer can lead to severe consequences and undercharging a customer is bad for business. Accuracy and reliability — that’s Rice Lake’s best habitat. The BCi scale/920i indicator combination is used throughout the lifecycle of coal (among other materials), from the mine, to barge loading, to its final destination at the power plant. Hannah and I followed this journey and, for us, it was an eye-opening experience. I’m just glad we wore safety goggles.

Subscribe to Rice Lake Magazine

Sign in or create a Rice Lake website account to request a Rice Lake Magazine filled with application stories like this one be sent to you.

Account Sign In Create an Account

My Account

My Account