Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

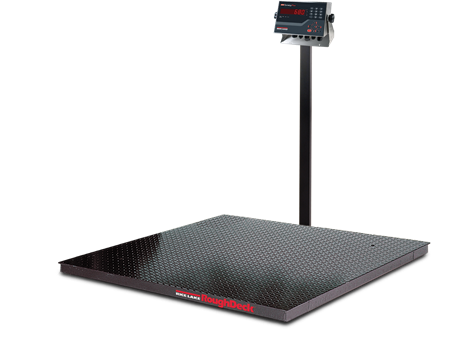

Getting to the Point of Point Loading

What is Point Loading

The manner in which a load is positioned upon a scale’s weighing surface can drastically impact scale performance and longevity. Most scales are designed to weigh a widely dispersed load. For example, a floor scale can repeatedly weigh large containers such as pallets because the load is spread out across a wide surface area. However, the same weight contained on a pallet can produce a much different result if it is not dispersed. If placed on a tote with casters, for example, the load creates focused points (rather than a dispersed load) upon the weighing surface. This is known as point loading.

Repetitive, near-capacity point loading can damage a scale’s physical integrity. A floor scale’s top plate may begin to warp at point loading locations, eventually leading to scale failure. Rice Lake Weighing Systems manufactures custom scales specifically designed for point loading. Featuring a thicker top plate, these scales can withstand non-dispersed loads.

Common applications include:

• Containers on wheels

• Pallet jacks

• Forklifts

• Repetitive weighing patterns or “traffic lanes”

Prior to selecting a scale, make sure you are aware of how the customer intends to use it. They may not be aware they are actually in a point loading application. Understanding their day-to-day weighing habits will help ensure they receive the scale best suited to their needs.

My Account

My Account