Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

How Does a Truck Scale Work?

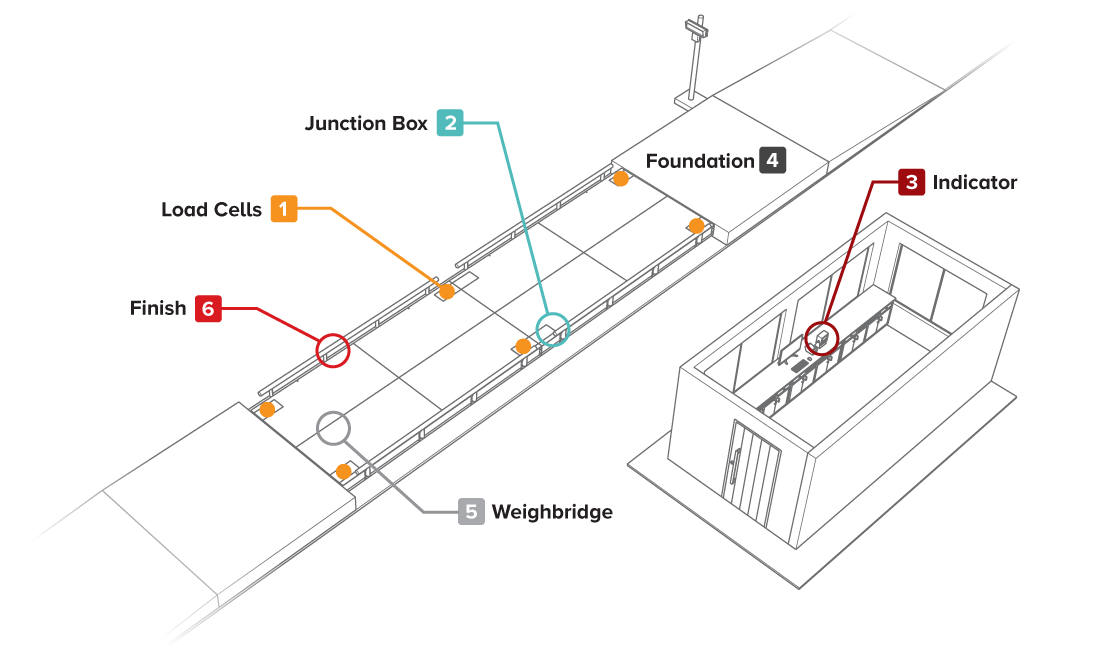

While truck scales may look simple from the outside, there are many complex components necessary for accurate and fast measurements.

Interior of a Truck Scale

To understand how a truck scale works, it’s important to know what’s happening inside the scale.

Load Cell

The load cell is a delicate piece of a truck scale. Multiple load cells are placed throughout the scale to accurately detect weight, and the load cells flex when a truck passes over. This flexing impacts the electrical signal traveling to the strain gauge inside the load cell, and the resulting signal is sent to the junction box.

Junction Box

Electrical signals from load cells are transmitted to the junction box. The junction box calculates the truck’s weight by equalizing load cell signals. Depending on the instrumentation, the load cells or the indicator can calculate the weight.

Indicator

The indicator, typically wired near the truck scale, will display the final weight. The indicator is the control terminal, capable of managing in/out truck programs and printers with additional programming.

Exterior of a Truck Scale

The exterior features of a truck scale keep it stable and reliable, and can be customized to suit a company’s brand.

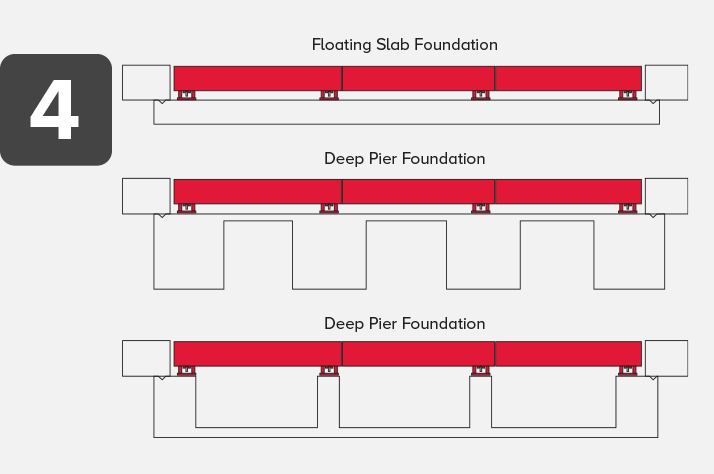

Foundation

The scale is installed on top of a foundation to keep it level and steady. Foundation designs such as pier, floating slab and pit are most common. The best foundation depends on the needs of the application and environment.

Weighbridge

The weighbridge is the large steel or concrete deck that trucks directly drive over. It houses the load cells and wiring. Ease of installation and access points to load cells depends on the manufacturer.

Finish

The scale’s finish protects it from the elements, typically done with urethane liquid paint or powder coating. The color varies depending on the manufacturer or customization opportunities.

Alternative Truck Scale Designs

Stationary truck scales function with these components. However, truck scales get more complex when considering alternatives for unique applications.

Portable Scale

A portable truck scale uses wireless wheel pads positioned under each truck wheel. The weights from each pad are sent to a remotely paired indicator to calculate the Non-Legal for Trade weight.

Large single-draft portable truck scales are another alternative, suited for temporary applications, but can be moved only using equipment. These scales are Legal for Trade.

Axle Scale

An axle scale is a smaller device, so it weighs each axle individually, and then the junction box calculates the overall weight. This is known as axle weighing, compared to single-draft weighing, which is when the whole truck is weighed at once. Scales that use axle weighing are not Legal for Trade.

In-motion Weighing System

In-motion weighing relies on an indicator with in-motion software and a speed sensor. Using a single-draft in-motion weighing system, vehicles are weighed while crossing the scale at low speeds, reducing the time trucks spend idling.

Buying and Installing

To purchase a truck scale, prospective buyers typically go through a supplier. Once a scale is chosen, manufacturing begins, and the installation is discussed. Depending on the manufacturer, scales may be customizable and made to order.

For new sites that require a foundation, construction takes longer as the concrete must cure prior to installation. Truck scales are an investment, so plan out the process to ensure it’s finished on time.

Rice Lake Weighing Systems’ SURVIVOR® truck scale line is a durable and accurate solution to vehicle weighing designed to last decades. Rice Lake also offers portable, axle and in-motion weighing solutions. Speak with a representative today to find the perfect scale for your application.

My Account

My Account