Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

How to Check Load Cell Signal

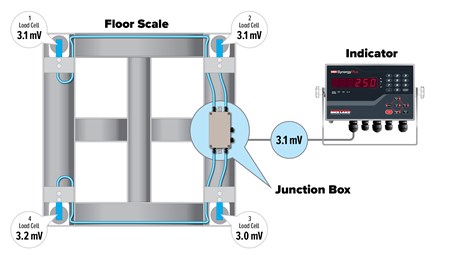

Load Cell Signal

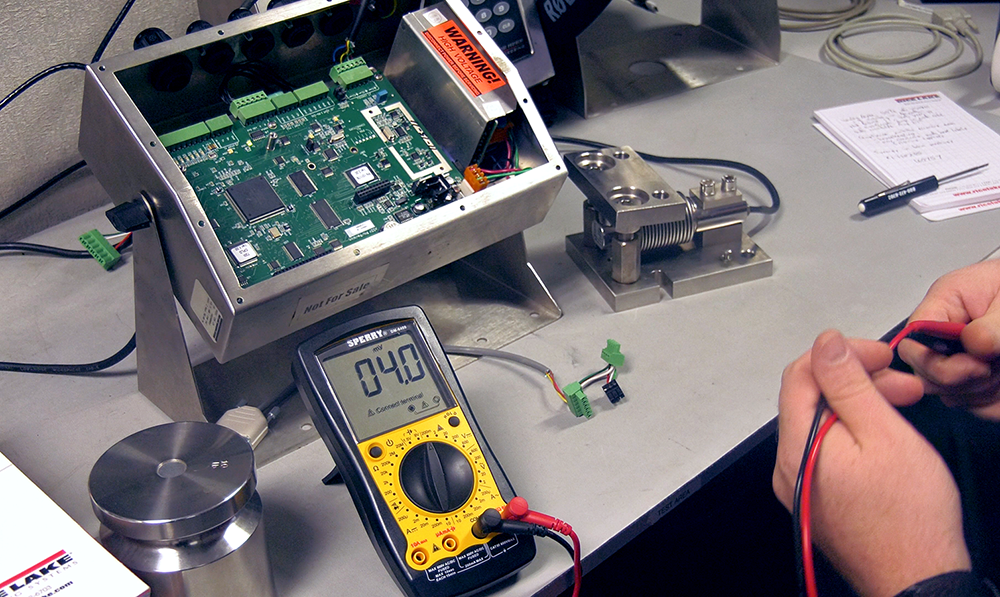

If you are getting unusual weight readings on your scale, the first thing you should do is check the load cell’s signal. When checking the signal of a load cell, you are watching for a change in the number of millivolts being sent to the display of the scale. To test the load cell’s signal, you’ll need a calibration weight, a voltmeter and an indicator.

To ensure the voltage is being sent successfully, consult the load cell’s wiring guide to connect the load cell to the scale input port of the indicator. Set the voltmeter to the DC millivolts setting and place the calibration weight directly on the load cell. Touch the red lead to the positive signal line and the black lead to the negative signal line. Ensure the correct color lead is touching the correct position on the scale input port.

If the leads are positioned correctly and the load cell is displaying the correct reading, then the load cell is working properly. If your leads are switched, your voltmeter will show a negative reading. If you get a reading above the scale’s capacity, an overloaded message will appear on the indicator’s display. This means there is a problem with the load cell’s signal and you can continue troubleshooting to resolve the problem.

If you cannot determine the cause of the irregular load cell readings, contact the manufacturer for additional support. Rice Lake Weighing Systems’ technical support team is available to assist with your scale questions, ensuring your system will weigh accurately.

My Account

My Account