Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

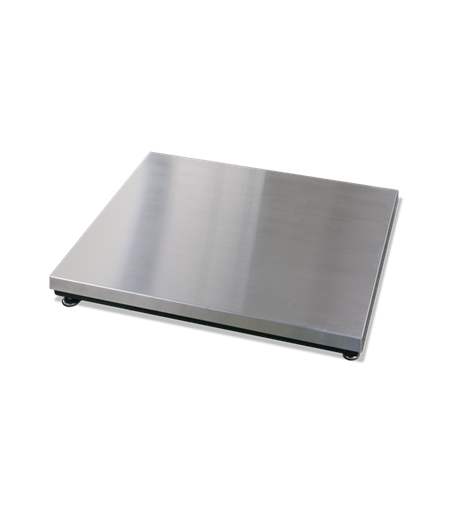

How to Choose a Bench Scale

Choosing A Bench Scale

Bench scales are everywhere and are used in various industries, such as shipping and receiving, manufacturing, and food processing! Bench scales have a compact footprint, making them ideal for processes with limited space. When selecting a bench scale, you need to consider a few factors before you choose one: the material, type of top, capacity and size of the scale, accessories, industry requirements and manufacturer support.

Material

It is essential to ensure the bench scale's construction is suitable for the environment. You should consider a stainless steel bench scale for applications involving corrosive materials or heavy washdowns. Stainless steel operates well in corrosive environments because it does not rust or corrode easily. For less demanding applications, a mild steel bench scale could be a comparable alternative to a stainless steel one.

Bench Scale Tops

Another thing to consider when choosing a bench scale is the scale’s top: flat top, ball top or roller top. A flat-top bench scale is used in many diverse industries for general purposes. A ball-top bench scale has multiple moving cylinders built into the top that allows a package, for example, to be rolled on or off the scale in any direction. The roller-top bench scale has multiple rollers built into the top, allowing the item being weighed to move forward or backward along a production line.

Capacity and Size

Before choosing a bench scale, evaluate the items you will be weighing. Observe the dimensions and weight of the smallest and largest items to determine if the capacity and size of a single bench scale would be suitable. If not, you will need an additional scale to obtain accurate weighments. While choosing a bench scale, you should ensure the scale’s capacity is higher than the heaviest object that will be weighed.

Industry Requirements

When considering bench scale options, it is important to understand the installation guidelines required for approval. For example, selling goods based on weight involves a Legal for Trade installation, which requires the scale’s measurements first to be certified. This certification is performed by scale technicians accredited by the region’s government. Scales used in hazardous environments have additional certifications. The desired bench scale must meet the safety requirements for potentially explosive environments.

Bench Scale Accessories

You should also consider the types of accessories you may need. Will your scale require any type of mobility or extra indicator columns? Depending on your manufacturer, they may be able to provide you with a portable bench scale or a mobile scale cart to securely hold your bench scale in place while providing extra mobility. A bench scale indicator column holds the associated indicator (if one is needed) above your bench scale for easy weight readings.

Manufacturer Support

Lastly, you should find a manufacturer and local scale dealership to support you during the selection process, installation, and regular calibration and scale maintenance. Rice Lake Weighing Systems works with an extensive network of authorized dealers who are ready to help you during the selection process. Rice Lake also offers in-house technical scale specialists who can assist with product selection and create custom bench scale solutions.

My Account

My Account