Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

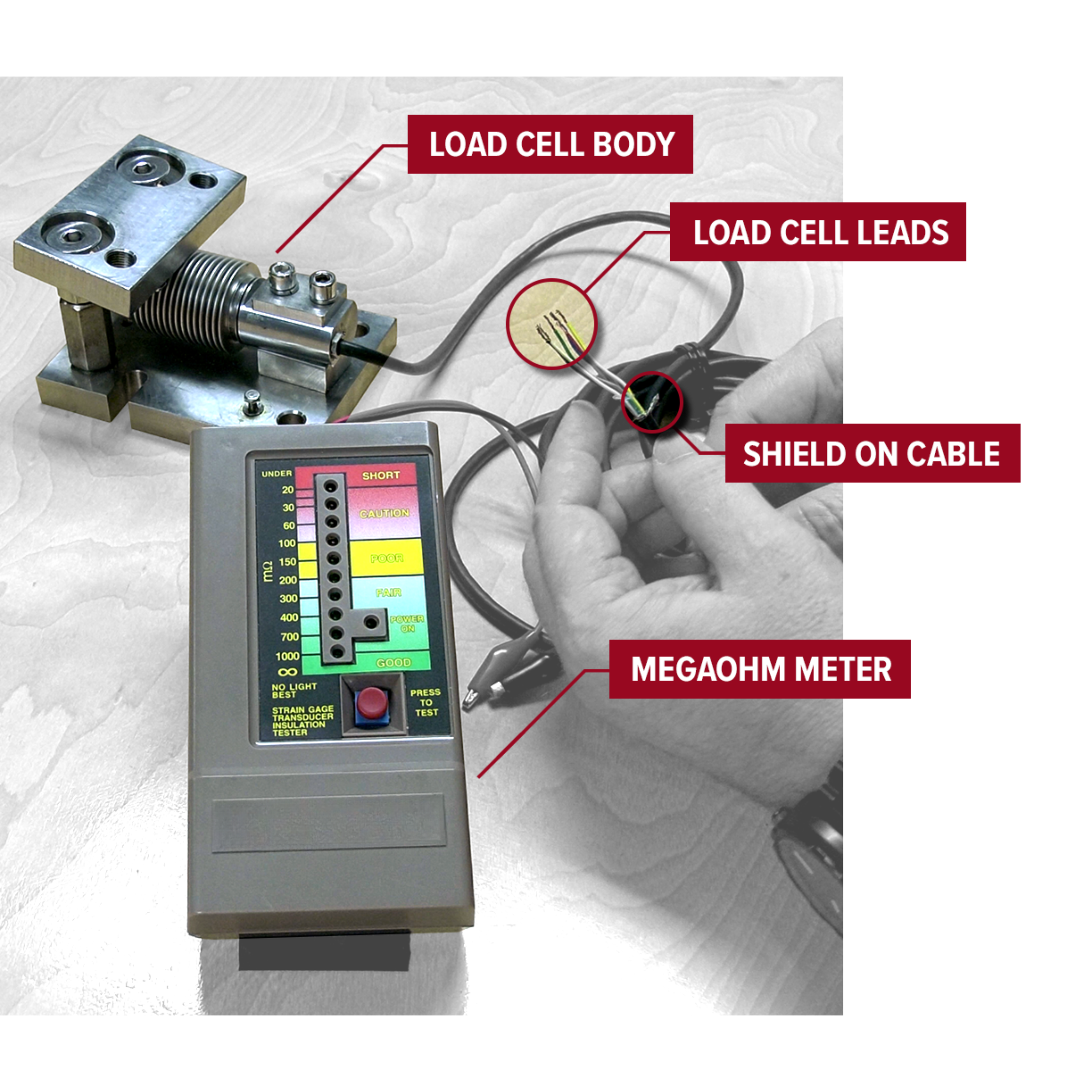

How to Test a Load Cell for Leakage

Detecting and Solving Load Cell Leakage Issues

If you are experiencing unstable weight readings, load cell leakage could be the cause. Electrical leakage is the transfer of electrical energy through insulation. This is usually caused by water damage from environmental factors, such as high humidity. The following test can be performed to confirm whether electrical leaking is the issue.

The first step in testing a load cell for leakage is to disconnect the cell from the indicator or junction box . You will need a megaohm meter that can read in hundreds of mega ohms . To prevent damage to the load cell, ensure that the megaohm meter doesn’t apply more than 50 volts of test voltage.

There are three ways to test for leakage:

- Connect one lead from the megaohm meter to the load cell wires and the other lead to the cable shield.

- Connect one lead to the cell wires and the other lead to the body of the cell or some piece of the framework that is in direct contact with the cell.

- Connect one lead to the body of the cell and the other lead to the cable shield.

During testing, ensure that you don’t touch the two connections from the megaohm meter since this can affect the reading. A reading greater than 1,000 mega ohms means the load cell is functioning properly. Any less indicates cell leakage.

Should you find that your load cell is leaking, you should have it replaced. Consult with Rice Lake Weighing Systems’ technicians to assist in selecting and replacing your load cell.

My Account

My Account