Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

Overhead Weighing Safety Guide

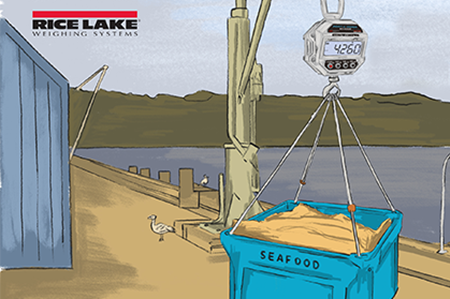

Overhead weighing solutions provide real-time measurement of the operational load and immediate feedback to operators and safety systems that prevent or limit unsafe conditions. By utilizing weighing equipment either as an accessory or integrated into a crane, accidents can be significantly reduced or prevented.

Are You Thinking About Crane Safety?

With today’s prevalence of overhead cranes in industrial applications, transporting materials has never been more convenient. However, with this convenience comes additional safety threats through improper crane use and maintenance. Common causes of crane accidents include caught load, slackline, over- or underload, and structural fatigue. With Rice Lake’s MSI overhead weighing solutions, federal OSHA and local regulatory requirements are exceeded to ensure compliance with safety standards. MSI systems are available as below-the-hook and integrated weighing solutions to ensure overhead weighing remains as safe as possible.

Below-the-Hook Weighing Solutions

Below-the-hook weighing solutions offer an added convenience of weighing in process—eliminating additional stops in shipping and receiving, material handling, metals and manufacturing. These solutions quickly provide operators lifted load weight with optimal balance capabilities. Below-the-hook crane scales can be used in medium to heavy-duty applications to prevent overload and alert the operator to potentially unsafe conditions.

MSI-3460 Challenger 3 Crane Scale

The MSI-3460 with ScaleCore provides industry-leading weighing features plus much more. Product operating time is extended to over 80 hours with a single six-volt rechargeable battery. The MSI-3460 has a NEMA Type 3/IP65 enclosure and maintains minimum 200% safe and 500% ultimate load ratings.

MSI-4260 Crane Scale

The MSI-4260 crane scale is built for heavy-duty dynamic weighing, includes a 5:1 safety factor, and exceeds OSHA, ANSI and ASME safety requirements. These solutions can be paired with advanced process controllers and RF solutions to offer complete industry solutions that easily integrate into existing configurations.

MSI-9600HT Hi-Torque Port-A-Weigh Plus Crane Scale

The MSI-9600HT Hi-Torque Port-A-Weigh Plus crane scale, integrated with ScaleCore technology, has models with up to 200,000-pound capacity that capture weight with ± 0.2% accuracy. The enclosure, made with IP66 marine-grade alloy anodized aluminum, features a rear-battery casting with snap-closure—keeping everything weathertight.

MSI-7300 Dyna-Link 2 Dynamometer

Dynamometers for light-duty, straight-lift weighing measure both vertical and horizontal tension. Constructed of high-grade, aircraft-quality aluminum with an anodized finish and gasket sealing, the Dyna-Link 2 is built to address caught-load or slack-line issues that may cause unsafe conditions.

Integrated Overhead Weighing Solutions

Most bridge, monorail, jib, gantry and straddle crane safety systems employ an integrated load sensing system. An integrated load sensor is designed to be permanently installed and placed where load is consistently applied relative to the actual load the crane is handling, generally with a sheave pin, load link or compression design. Because of their design, these solutions feature no loss of head height. In addition to the sensor, the system must have a load indicator to provide operators with load indication and control.

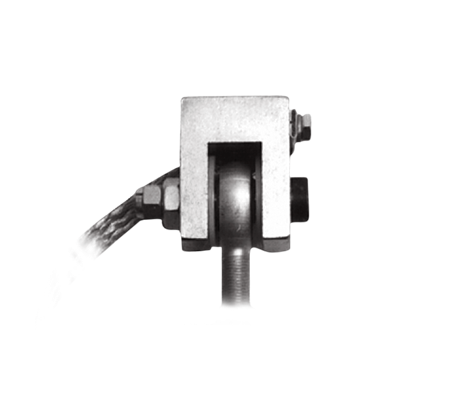

Clevis Load Pin Sensor

A key component for MSI’s integrated overhead weighing solutions is the Clevis Load Pin Sensor. Typically designed and manufactured specifically for each unique system, the MSI load pin ensures the most efficient and accurate performance for each specific installation. MSI load pins utilize only internally mounted strain gauges for complete environmental protection.

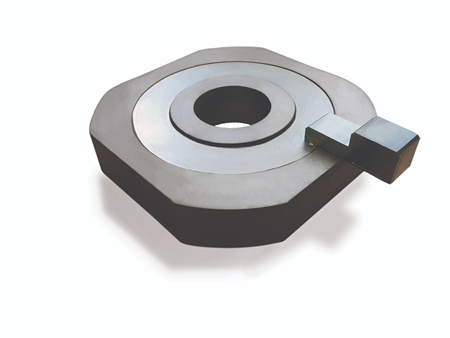

Shear Web Load Cell

MSI’s Shear Web Load Cell can be custom-fit for use with existing equipment. The load cell can be interfaced with a wireless RF transmitter to communicate load data with a digital weight indicator or handheld remote display.

TranSend™ Wireless Load Cell Interface

TranSend is a wireless load cell interface that transforms the signal of one or more load cells and transmits the data wirelessly to a receiving unit. Multi-channel devices offer up to three optional relay contacts, an audible alarm, and can function as a smart junction box.

Digital Weight Indicators and Process Controllers

For real-time data and event-based response and logging, digital weight indicators, process controllers and signal conditioning transmitters easily integrate with overhead solutions. These devices can trigger relays for external alarms, warning lights and emergency stops. Integration with PLCs and data logging systems provides load tracking while in operation as well as prompt indications of improper use. RF remote displays provide complete scale interaction while allowing operators to maintain a safe distance from lifted loads and equipment.

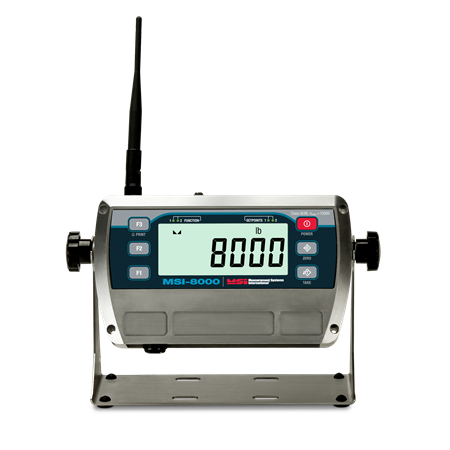

MSI-8000HD Indicator/RF Remote Display

MSI-8000HD is a heavy-duty, handheld indicator and RF remote display. The full waterproof construction resists most elements making it especially resilient. The MSI-8000HD is fully compatible with all ScaleCore crane scales and dynamometers.

MSI-8004HD Indicator/RF Remote Display

MSI-8004HD features the same rugged versatility as the MSI-8000HD with a larger, more vibrant, LED display. With the option to view the display in either red/green or blue, the MSI-8004HD provides longer viewing distances for more diverse environments and applications.

Rice Lake Weighing Systems offers a wide range of overhead weighing solutions. Work with a Rice Lake overhead weighing system expert to find the right solution for your process.

My Account

My Account