Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

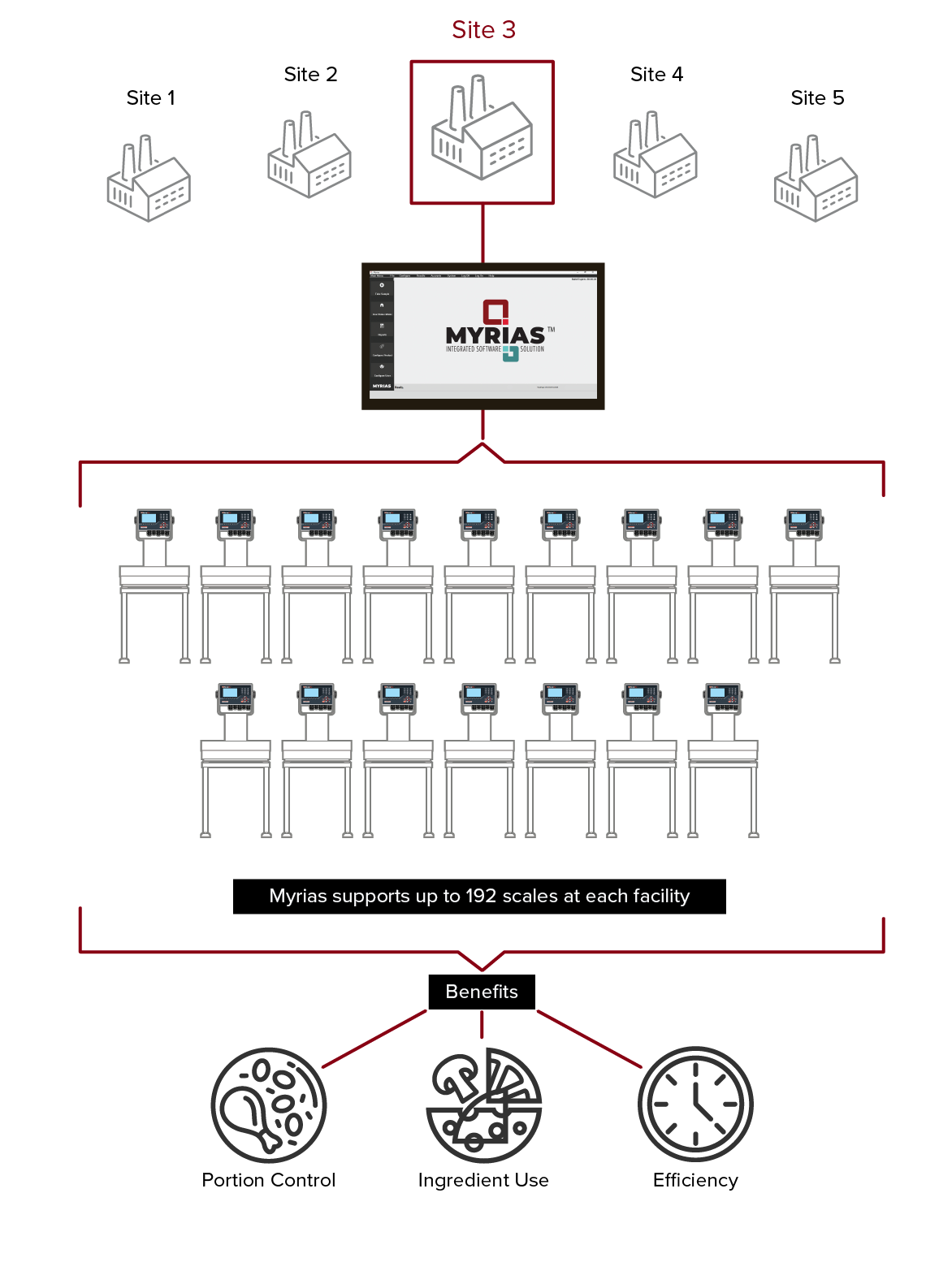

Portion Control with Batching Software

Food production is a carefully regulated industry and requires careful control of ingredients. One producer of chilled and shelf-stable food took control of their process by implementing Myrias® batching software.

The Challenge

A European-based producer of chilled and shelf-stable food needed to upgrade their batching processes at multiple production sites. Each facility produces different recipes for ready-made meals, including sandwiches, salads and pasta salads—the types of food you might expect to find in convenience stores.

They needed to replace numerous scales that were outdated and no longer performing as well as needed. The company also needed better control over the use of high-cost ingredients, ensuring they weren’t over-using material, causing higher production costs.

The Solution

This prepared-food producer chose to implement Myrias software from Rice Lake Weighing Systems, and 300 scales and end-of-line industrial PCs from their scale dealer. Rice Lake’s Myrias software works with a wide range of scale indicators, so it could easily integrate with the new scale systems. The Myrias software program was customized to accommodate the company’s wide array of scales—not just the newest ones installed by the dealer.

This Myrias solution can support up to 192 scales at each facility, and provides workflow flexibility by allowing any scale to be assigned to any line using end-of-line stations. Operators receive real-time feedback on ingredient quantities, ensuring they’re optimizing the use of high-cost ingredients and staying within tolerance limits. Myrias also provides traceability for finished products, helping the company maintain compliance with food production regulations.

The combination of scales, industrial PCs and Myrias batching software was implemented at five different sites, optimizing ingredient use, improving portion control and increasing operational efficiency.

Subscribe to Rice Lake Magazine

Sign in or create a Rice Lake website account to request a Rice Lake Magazine filled with application stories like this one be sent to you.

Account Sign In Create an Account

My Account

My Account