Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

Properly Welding on Structures with Load Cells

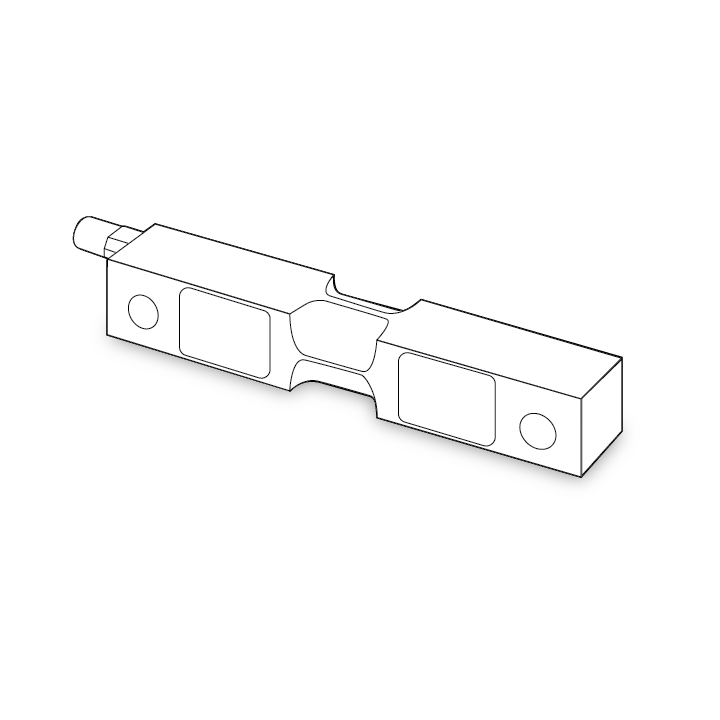

A load cell's accuracy and structural integrity can be compromised if mistreated, including from welding near the load cell, or on the weighing structure itself.

Load cells are the most important component of a weighing system. Although they are often heavy, appear to be a solid piece of metal, and are constructed to accurately weigh up to tens of thousands of pounds, load cells are actually very sensitive devices. Their accuracy and structural integrity can be compromised if mistreated. This includes welding near the load cell, or on the weighing structure itself, such as a silo or vessel.

The current produced from welding is much higher than the current a load cell is typically constructed to withstand. In addition to electrical current exposure, welding can also expose load cells to high temperatures, welding splatter and mechanical overloads. Most load cell manufacturers’ warranties do not cover damage to load cells due to welding near a cell if they are left in place. Therefore, it is always best to remove a load cell prior to welding if possible.

Removing Load Cells Prior To Welding

To ensure welding will not damage your load cells, remove them prior to any welding on the structure. Even if you are not welding near the load cell, it is still recommended to remove all load cells prior to any welding.

- Inspect the entire system for electrical connections and grounding.

- Turn off all sensitive electrical equipment on the structure. Never weld on an active weighing structure.

- Disconnect the load cell from all electrical connections.

- Ensure the weigh module or assembly is securely bolted to the structure, then safely remove the load cell.

- Insert a spacer or dummy load cell in its place for the entire welding duration. If needed, use appropriate lifts or jacks on suitable jacking points to raise the structure safely to remove load cells and replace them with dummy cells. Inspect the mechanical assembly before carefully lowering the structure back onto the weighing assembly with dummy cells.

- Ensure all welding grounds are in place prior to starting the welding work.

- When welding is complete, return the load cells to their assemblies. Inspect the mechanical integrity, reconnect electrical equipment and turn on. Scale calibration may be required at this point.

Welding When Unable To Remove Load Cells

When removing a load cell prior to welding is not possible, take the following precautions to protect the weighing system and minimize chances for damage.

- Inspect the entire system for electrical connections and grounding.

- Turn off all sensitive electrical equipment on the structure. Never weld on an active weighing structure.

- Disconnect the load cell from all electrical connections, including at the junction box.

- Insulate the load cell from the ground by connecting the input and output leads, then insulate the shield lead.

- Place a bypass cable to reduce the flow of current through the load cell. Do this by connecting the upper load cell mount or assembly to a solid earth ground, terminating with bolts for low-resistance contact.

- Ensure all welding grounds are in place prior to starting the welding work.

- If space allows, place shields to protect the load cell from high temperatures and welding splatter.

- Be aware of mechanical overloading conditions and prevent them.

- Keep welding near the load cell to a minimum and use the highest allowed amperage with an AC or DC welding connection.

- When welding is complete, remove load cell bypass cable and inspect the mechanical integrity of the load cell mount or assembly. Reconnect electrical equipment and turn on. Scale calibration may be required at this point.

Never Weld a Load Cell Assembly or Weigh Module

You should never weld a load cell assembly or weigh module directly. Doing so voids all warranties and compromises the weighing system's accuracy and integrity.

Consult the Manufacturer

All weighing structures are unique and should involve a licensed scale engineer or manufacturer’s consult prior to welding. Rice Lake Weighing Systems can help provide this consult and offer guidance and best practices prior to welding weighing structures.

My Account

My Account