Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

Protect Your Belt Scales from Father Winter

Regular belt scale with maintenance is even more important in the winter when ice buildup becomes a risk.

Belt Scales Winter Maintenance

Regular belt scale maintenance includes clearing the scale area of debris, checking the condition of the idlers, check rods and belt, and zero testing the scale daily. This maintenance is more important in the winter when ice buildup becomes a risk.

Weigh Frame Cleanliness Is a Must

Debris in the scale area can vary in the winter from mud to snow to ice, depending on the temperature. Any damp material on the scale weigh frame can freeze, causing issues like inaccurate zero test results and false totalizing. Frozen material buildup will need to be cleared by either scraping it away or using a dead blow hammer to carefully loosen it.

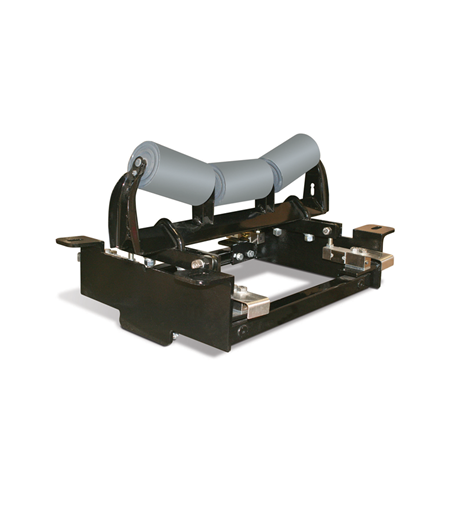

The most important part of conveyor belt scale maintenance is keeping the weigh frame clean. Ice buildup occurring anywhere load is introduced to the scale, including the idlers, can impact the weight reading. The ice buildup won’t necessarily impact calibration, but it will add extra weight to the weigh frame so the scale registers false numbers.

If a belt scale weigh frame has just five pounds of ice buildup, less than a gallon of water, the scale could register several extra tons every hour, causing a false totalization.

Need-to-Know Winter Maintenance

Cold weather can cause the conveyor belt to contract, or shrink, and become stiff. Allowing the conveyor belt to run for 10 to 15 minutes without a load will warm the belt, making it more pliable, ensuring reliable scale use.

Keep Your Scale in Prime Condition

Performing a daily zero test on the conveyor scale will help indicate when the weigh frame needs to be inspected. A weight indicator like the 882D belt scale indicator will be able to perform daily zero and calibration tests to monitor scale functionality. In good weather, the zero test should have normal results close to 0.1 or 0.2 percent repeatability but if the zero test results are more than 0.25 percent repeatability, the weigh frame should be checked for ice buildup.

After clearing any debris from the belt scale weigh frame, another zero test should be performed. The next step would be to run a span test, or static calibration test, especially if a dead blow hammer was used to loosen any ice buildup. If the span test results are not normal compared to periodic span tests, it is best to call a certified scale dealer to perform a thorough inspection and any calibrations necessary.

The speed sensor on the conveyor belt also needs extra attention in the winter. Whether the speed sensor is a tail wheel sensor on the return side or a shaft-mounted encoder, it must be clear of ice before start-up. If the scale uses check rods, these should also be inspected for water and ice buildup and cleaned before use.

Combating Debris Buildup

Legal for Trade belt scales require a canopy, called a tunnel, to protect the conveyor from extreme weather. Covering the conveyor scale’s weigh frame is the only way to prevent ice and snow from building up on the scale, though it is not practical for every application. If the conveyor does not have a tunnel, the best way to clear the ice is to scrape it off or use a dead blow hammer to carefully loosen it, then scrape it off.

Keeping the weigh frame clear of debris and performing daily zero tests are the best ways to keep a conveyor belt scale operating through winter. A weight indicator, like the 882D, designed to work with belt scales will withstand harsh environments to help monitor belt scale functionality year-round.

My Account

My Account