Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

The Basics of Load Cell Wiring and Trimming

Load cell wiring and trimming are critical to a weighing system’s accuracy and should always be performed by trained technicians. However, general load cell wiring knowledge can help you better understand how your weighing system works and how potential errors occur.

Load Cell Wiring Basics

Load cell cables typically have four or six wires. Both versions have positive and negative signal and excitation lines, though a six-wire cable also has positive and negative sense lines. Sense lines are linked to the sense connections of the system’s indicator, sometimes through a junction box, allowing the indicator to sense a load cell’s actual voltage.

If there is a voltage drop between the indicator and load cell, the sense lines send that information to the indicator, which automatically adjusts voltage. This compensates for the loss of voltage or amplifies the return signal to compensate for loss of power to the load cell.

Load cell wires are color coded to help ensure proper connections. Different brands use different color codes, which is why there are load cell wiring guides available for technicians to use during installations.

Understanding Load Cell Trimming

Load cell trimming is sometimes called load cell summing because it involves tying or summing multiple load cell output signals together. This happens in a junction box, also known as a summing box, which sends one system signal to the indicator.

It’s necessary to trim load cells in a multi-cell system when the weight distribution to each load cell isn’t equal. For example, in vessel loading processes, the presence of agitators or the type of material, such as powder, can affect how material and weight are distributed to each load cell. Additionally, it’s nearly impossible to make every load cell exactly alike. Tolerances in the manufacturing process allow for some variation in individual load cell specifications, which, if trimming isn’t applied, doesn’t allow for the accuracy necessary for most applications.

Types of Load Cell Trimming

There are two different types of load cell trimming that scale technicians rely on when installing multi-cell weighing systems.

Excitation trimming is the oldest method of trimming load cell output signals. Excitation trimming adds series resistance to the excitation circuit of the load cell, reducing excitation voltage at the load cell. The system load cell with the lowest output receives the full excitation voltage, while the other system load cells receive proportionately smaller excitation voltages. This creates matched outputs for all load cells in the system.

Signal trimming is the most common and popular type of trimming because it is the easiest to use. Signal trimming is compatible with nearly all indicators and is relatively unaffected by temperature changes or excessive system vibrations. It involves adding a relatively high parallel resistance between the signal of each load cell, which creates a leakage path that diverts some of the available load cell signal away from the indicator. More load cell signal will be available to the indicator as parallel resistance increases.

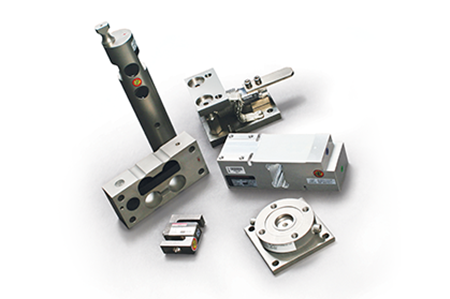

Rice Lake Weighing Systems’ Load Cell and Weigh Module Resource Center provides additional information on load cells and weigh modules, including links to resources such as Rice Lake’s Load Cell Wiring Guide and Load Cell and Weigh Module Handbook.

My Account

My Account