Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

The Future of Shipping Is Dim Weight

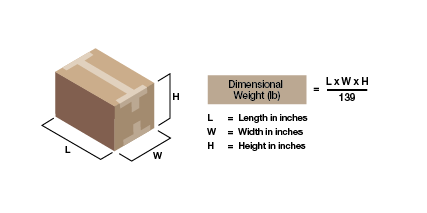

What is Dimensional Weight?

To more accurately reflect billable weight, large carriers such as FedEx®, UPS® and DHL® are determining shipment pricing based on either dimensional weight or actual weight—whichever is greater. Dimensional weight, often referred to as dim weight, reflects the package’s density—the amount of space the package utilizes in relation to its weight.

To determine dim weight, a package’s length, width and height are multiplied, resulting in its cubic size, and then divided by 139.

When lightweight items are shipped in large packages, carriers can reach maximum volumetric capacity in their shipping containers before reaching weight capacities. To maximize carrier capacity and efficiency, dim weight policies prompt shippers to package their items more efficiently and with less wasted space. Companies who ship packages without correctly calculating dim weight could pay increased shipping costs from miscalculated dimensions or freight compliance issues.

How Can Dimensioners Optimize Shipping?

How can businesses ensure freight compliance and deter revenue loss from miscalculated dimensions without adding extra time? Incorporate a dimensioning system into the shipping process. Dimensioners use sensing and imaging technology to calculate the dimensions of packages to determine dim weight. They provide valuable solutions to ensure companies optimize dim weight shipping with accurate package dimensions without slowing processes.

Rice Lake’s Dimensioning and Weighing Solutions

As a leading manufacturer of dimensioning and weighing systems, Rice Lake Weighing Systems offers a range of package and pallet solutions. Rice Lake’s team of dimensioning experts are available to answer questions and help you find the best solution for your processes.

My Account

My Account