Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

Top 10 Ways to Improve Dim Weight Shipping

Logistics and shipping departments rely on many moving parts to keep operations going. Ensure your shipping departments smoothly calculate dimensional weight by following these steps.

Why Use Dimensional Weight?

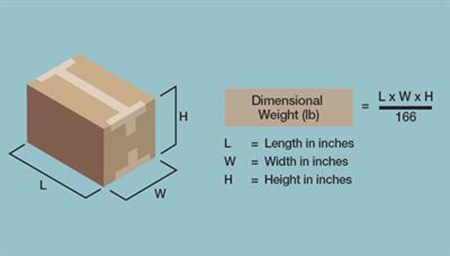

From small businesses and mail counters to large operations and warehouses, parcel and package shipping is used in many industries. Businesses rely on carriers to set guidelines for package sizes and costs. To determine pricing, carriers use dimensional or actual weight—whichever is greater.

Measuring dimensions manually is a time-consuming process compared to calculating actual weight with a conventional shipping or postal scale. How can businesses ensure freight compliance and reduce revenue loss from miscalculated dimensions without adding time to their process?

Manufacturers are modernizing dimensioning technology to provide solutions that efficiently and accurately obtain the dimensional weight of packages. Dimensioners use sensors and cameras to determine dimensional weight. Although dimensioners differ in performance and technology, all models provide a valuable solution by ensuring companies can calculate dimensional weight accurately and efficiently.![]()

Follow these steps to optimize dimensional weighing in your application:

-

Optimize Shipping Packaging

Package items safely. Use only the necessary material to safely ship products and accurately sized containers.

-

Use Quality Packaging Materials

Packaging materials should have strength, durability and reduce empty space. To have a smaller dimensional weight, the volume must be smaller. -

Know Shipping Fees

Speak with carriers to determine their dim weight policies. Knowing shipping requirements can reduce compliance fees in the future. -

Track Shipping Documents

Document your total monthly shipping charges to ensure you’re measuring accurately and being charged properly. -

Convert to Cubic Measurements

Even with irregularly shaped packages, ensure you take cubic measurements. Polybags, tubes and irregular shapes still need proper measurements for accurate dimensional weight. -

Streamline Shipping Operations

Especially with irregular packages, make sure shipping departments take the time needed to get accurate measurements. -

Find The Right Equipment

Invest in a dimensioner to make processes faster. Save time and improve package measurement accuracy. -

Know Your Department

If you ship a variety of items, from oversized packages to thin mailers, closely research your largest package heights and widths. Ensure the systems you invest in can fit the range of packages shipped. -

Compare Specifications

Different dimensioners and software offer unique features. Certain dimensioners can integrate scales to provide package dimensions and weight at the same time. Others can share this data with existing shipping software. -

Consider Long-term Maintenance

Maintenance and support are a big factor to consider when upgrading systems. Ensure you invest in equipment that lasts.

Rice Lake Weighing Systems’ Dimensioners Optimize Shipping

Rice Lake offers a range of dimensioning systems for pallet and parcel shipping departments. Calculate dimensions and weights in seconds, and integrate it easily with preexisting shipping software. Invest in a solution that makes shipping easy.

My Account

My Account