Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

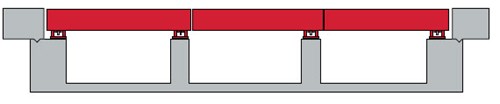

Truck Scale Foundations

Choosing a Truck Scale Foundation Type

Even the toughest scales are put at risk with a poor foundation. Many factors, such as the slope of the site and soil conditions, must be considered prior to construction. The ground must also be free of any settling prior to scale installation. If the foundation is not properly constructed according to the certified drawing provided by your truck scale manufacturer, your truck scale foundation could shift, causing the scale to be outside acceptable calibration tolerance. Concrete curing periods can vary depending on the type of concrete being used. Work with your scale supplier to integrate the foundation and approach design into your installation and site plan. Your scale supplier should also be able to recommend local contractors with truck scale foundation experience.

Aboveground or Pit Foundations

Until the early 1970s, all truck scales were mechanical and installed in expensive concrete pits. Today, most scales are installed aboveground or in concrete pits with floor foundations. With the benefit of new modular construction, scales can also be installed in a shallow pit, as opposed to the deep pit required by older mechanical scales. One of the biggest reasons for choosing a pit-type installation is space—or lack of it. A pit installation requires less space than an aboveground installation since longer approaches are generally required for aboveground foundations. However, pit-type scales require sump pumps and drains, and are more vulnerable to accelerated rust and corrosion due to the potential of standing water in the pit.

Pit |

Aboveground |

|

| Cost | More expensive due to additional excavation, reinforcing steel and concrete | Less expensive due to less construction work |

| Service and Scale Repairs | In some cases, can be more costly due to confined area restrictions, which often require gas detection devices and operator safety harnesses to be used | Less difficult/less costly and allows service from the deck of the scale |

| Clean Out | Often done manually and can be very time consuming “bucket by bucket” | Quick and easy—done with a water hose or air compressor from the side |

| Scale Inspection | Must be done from inside the pit | Can be performed by simply walking around the perimeter of the scale |

| Restrictions or Hazards | Some states require specified clearances underneath the scale. Must also meet with OSHA and confined space hazards regulations | Some states require specified clearances underneath the scale |

| Approaches | 10 feet flat and level | Often 10 feet flat and level |

| Ramps | Not required | Typically 25 feet long on each end of the approach. Often requires more real estate to install and operate |

| Electricity Needed | Typically has electricity for pit lights and sump pump if no gravity drain is present | No pit light or sump pump required |

Foundation Designs

Deep Pier Foundation

Typical for colder climates such as those found in northern areas of North America, the deep pier foundation places part of the foundation below the frost line to eliminate the negative effects that freeze-thaw conditions can have on foundations. Discuss with your scale supplier if a deep pier foundation meets your application requirements, or if a deep pier or other specific foundation design is required by your state and region. Similar to isolated pier foundations, the deep pier foundation also requires 2,500-3,000 PSF soil bearing pressure.

Shallow Pier Foundation

Shallow pier foundations are a cost-effective solution for truck scale sites with adequate soil compaction and a warmer climate that will not encounter frost line issues. Discuss with your scale supplier if a shallow pier foundation is best suited for your application and meets state and regional requirements.

Floating Slab Foundation

A full slab foundation is a continuous or monolithic pour of concrete that runs the entire length of the weighbridge. This is the second most cost-effective type of foundation and is designed for ground that has a soil bearing pressure of at least 1,500 PSF. Discuss with your scale supplier if a floating slab foundation is ideal for your application and location, as well as meets state and regional requirements.

Pit Foundation

The pit foundation is available in numerous depths, from two to six feet. Your pit depth should best fit your needs as well as adhere to all federal, state and local requirements.

Drainage

Efficient water drainage around the foundation is key to preserve scale components. The installation site should have adequate runoff, allowing water to easily drain away from the scale. Areas with heavy rain and melting snow should take extra consideration when planning site drainage.

My Account

My Account