Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

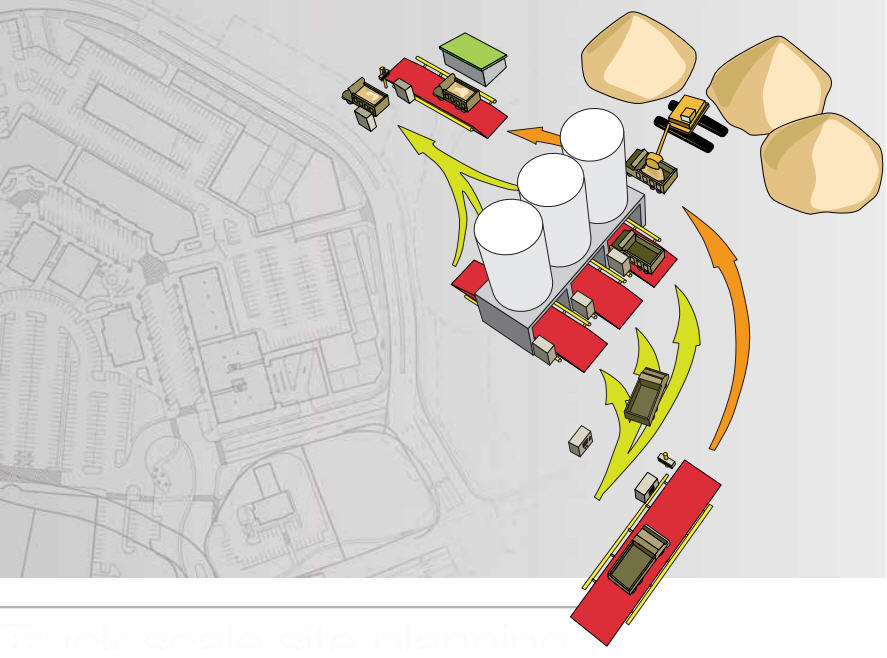

Truck Scale Site Planning

Truck scales are a big investment, so it’s important to plan ahead and design an optimized site.

Assessing Truck Scale Sites

To ensure the longest lifespan and best performance for your truck scale, proper site planning is essential. Your truck scale supplier can help evaluate the following:

- Traffic flow

- Foundation location

- Electrical and conduit requirements

- Soil conditions and drainage

- Ease of maintenance

- Accessory locations

Many factors can determine the ideal layout for a site, so take time to decide what’s best for you.

Mapping Operations

Before purchasing a new truck scale, draw a flow map of current or planned operations and determine areas for improvement. Ensure there is adequate space around the scale to perform maintenance and accommodate driver safety. If heavy traffic flow may cause a line, incorporate additional space for waiting trucks. Also, consider any special filling or dumping procedures that need space at the site.

Plotting Traffic Flow

Plan traffic patterns on your flow map, marking where trucks enter, load, unload and exit the site. Make sure there is plenty of room for drivers to maneuver. Once you’ve plotted the flow, take a test drive with a full-size truck, checking for any tight spots or safety issues.

Rice Lake Weighing Systems’ SURVIVOR® Truck Scales

Rice Lake offers the toughest truck scales to suit your site, no matter the environment. Built with longitudinal I-beams to maximize weighbridge support and integrity, SURVIVOR truck scales are a durable and accurate solution for truck weighing.

My Account

My Account