Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

What Are Loss-In-Weight Feeders?

Loss-in-weight feeders are ideal dosing systems for a variety of applications from bulk, dry materials to liquids and even poorly flowing materials. Loss-in-weight feeders can be used in many industries from food or chemical production to high-temperature or ATEX environments.

The Ideal Dosing System

Consistently Accurate Product Dosing

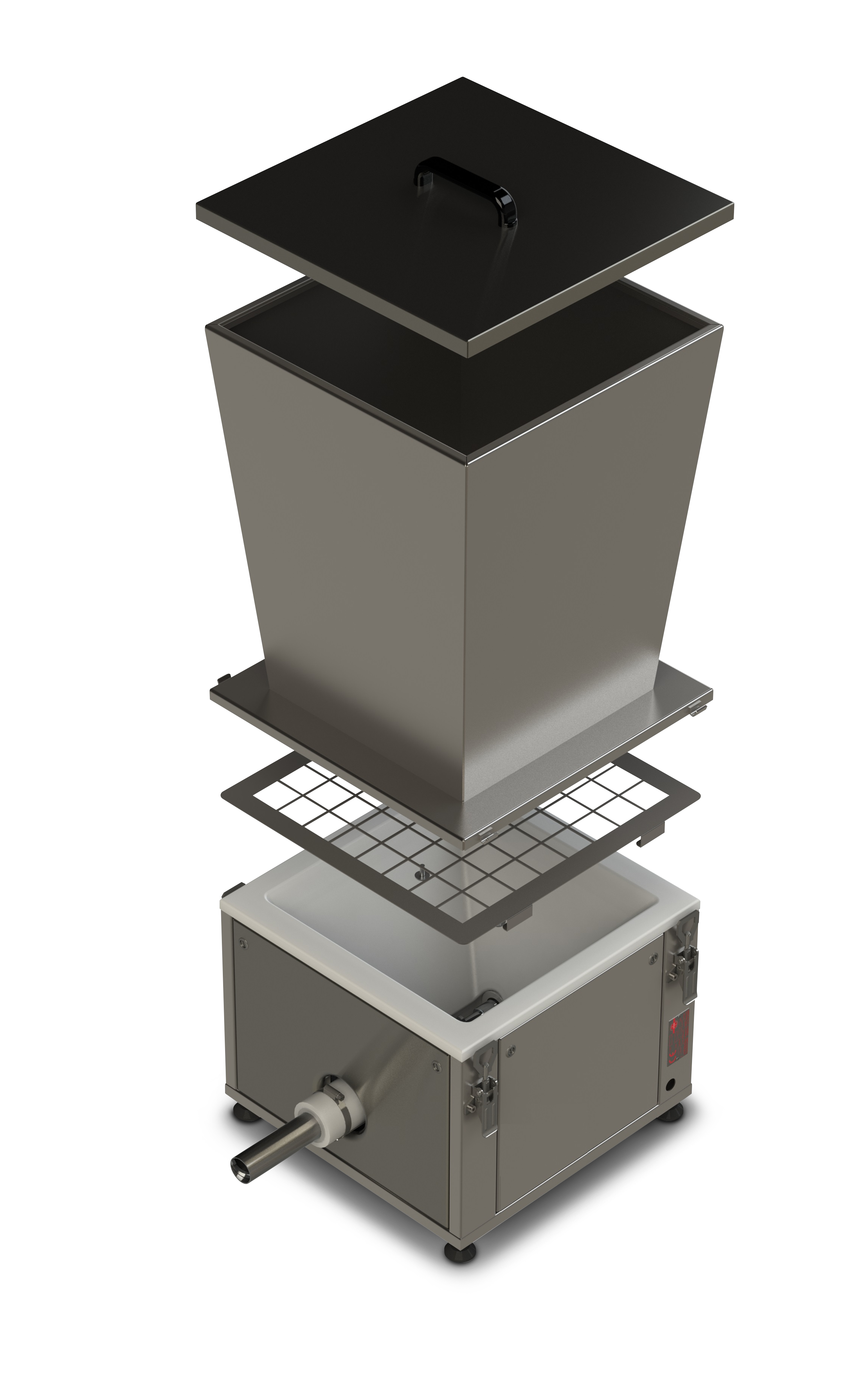

Loss-in-weight feeders consist of a hopper with a dosing unit, typically a screw or vibrating unit, all placed on load cells monitoring the material output of the hopper during dosing. Dosing is measured in kilograms per hour and the controller adjusts the speed of the dosing unit to match the setpoint, ensuring consistent product flow. The hopper on the dosing unit can be refilled manually or automatically from a storage hopper without impacting the flow rate or stopping production. The target flow rate for loss-in-weight feeders is controlled by a setpoint based on the dosing capacity, which is measured in kilograms per hour.

Fixed Dosing Systems

This loss-in-weight system is best for easy-flowing, dry products with straightforward dosing. Dosing is typically done with a vibrating unit or a screw and optional paddles to gently agitate the materials and prevent product build-up. When paired with paddles, the screw and paddles can either operate from the same motor or separate motors, giving users complete control over the output of the dosing equipment.

Flex Dosing Systems

Using a hopper with a flexible PU (polyurethane) insert, a flex dosing system is an ideal solution for products that are easily damaged or difficult to extract. Agitators move against the flexible walls of the hopper to keep product moving, ensuring there are no build-ups or compacted material. Dosing with this system is done with a screw, though the size and style of the screw are determined by the type of product and desired flow rate.

Liquid Dosing Systems

For continuous liquid dosing, a loss-in-weight feeder and pump are paired with a floor scale to precisely weigh the liquid as it fills a barrel or an IBC (intermediate bulk container). Similar to other loss-in-weight systems, the weight indicator controls the dosing speed of the pump. Because the container is connected to the pump through a flexible hose, the liquid travels straight out of the container providing greater accuracy than a standard flowmeter.

Loss-In-Weight Controllers

Rice Lake offers weight indicators and controllers that are ideal for use with loss-in-weight dosing systems. When paired with a fieldbus protocol, the setpoint from the PLC is sent to the controller to ensure accurate output using PID functions. When necessary, the controller adjusts the speed of the screw, vibrating unit or pump to maintain the requested capacity.

Whether you’re dosing products for chemical processing, food manufacturing or anything in between, loss-in-weight feeders are ideal solutions to accurately measure material flow rates. If you need help finding the best system for your application, Rice Lake Weighing Systems’ experts can answer all of your weighing and dosing questions.

My Account

My Account