Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

Which Crane Scale Is the Best Fit for My Application?

Crane scales are fundamental for countless applications, ensuring safety and accurate load measurements. When used properly, crane scales help minimize unsafe conditions by providing real-time measurements and immediate feedback to operators and safety systems. By exploring the goals of overhead weighing and analyzing aspects of your environment, you can determine the crane scale best suited for your application.

Overhead Weighing Goals

The size and capacity of the scale depend on its use. Before selecting a crane scale, decide its purpose. Are you focusing on load monitoring, process control or data integration?

Load monitoring prevents crane accidents, regulates compliance, maintains employee safety and protects equipment. To ensure compliance, the scale should meet or exceed OSHA, ANSI, ASME and other safety design standards, such as a 5:1 ultimate safety factor. Accuracy is generally 1-3% full scale.

Process control aims to deliver accurate weight data, real-time information and integration with manufacturing data acquisition systems. Accuracy is often 0.1% full scale.

Data integration systems strive to increase informational exactness and control, stream data to customer database programs, offer paperless abilities and reduce human error.

Crane Weighing Solutions

There are many reliable overhead weighing solutions available for various types of applications. Below are types of cranes and scales best suited for each.

Monorail Hoist

This is the most common hoist, which uses a chain hoist or a block with a wire rope or cable. It has a capacity of up to 10 tons and is most commonly found in industrial facilities. Rice Lake recommends the MSI-3460 crane scale.

Jib Crane

Jib cranes feature a horizontal support with a movable hoist. They are commonly seen in machine shops and are useful for checking the weights of smaller machine parts during or after production. Rice Lake recommends the MSI-3460 crane scale.

Semi Gantry Crane

A semi gantry is similar to a gantry crane, but one end of the bridge is supported on a fixed rail or runway by at least one leg. A truck running on an elevated rail or runway supports the bridge's other end. Rice Lake recommends the MSI-3460 crane scale.

Bridge Crane

Bridge cranes have a laterally moving trolley while the bridge moves longitudinally. This offers a wide range of motion, creates efficiency, easily integrates into existing applications and is ideal for safety. Rice Lake Recommends scale the MSI-9600HT, MSI-6360 or MSI-4260 crane scales.

Rail Mounted or Rubber Tire Gantry Crane

The rail-mounted or rubber tire gantry moves similarly to a bridge crane. It is found in heavy industrial facilities, where scale capacities can range up to 200 tons. Rice Lake Recommends scale the MSI-9600HT crane scale.

Integrated Weighing Solutions

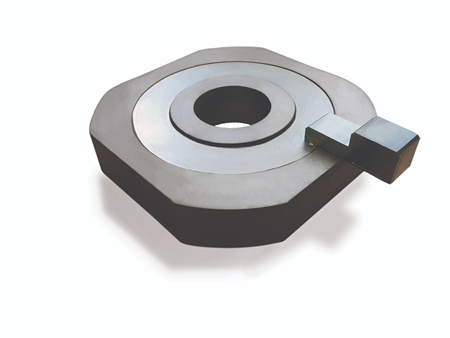

Most bridge, monorail, jib and gantry crane safety systems employ an integrated load-sensing system. An integrated load sensor is designed to be permanently installed and integrated where the load is consistently applied. These solutions are ideal for applications with limited space and preventing overload accidents.

Rice Lake Weighing Systems’ MSI

Rice Lake’s MSI brand of trusted overhead weighing solutions assists in creating safe and efficient operations. Rugged crane scales, plus integrated and communication solutions, can be integrated into nearly any industry or environment. Contact an expert today to discuss the perfect crane scale solution for your application.

My Account

My Account