Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

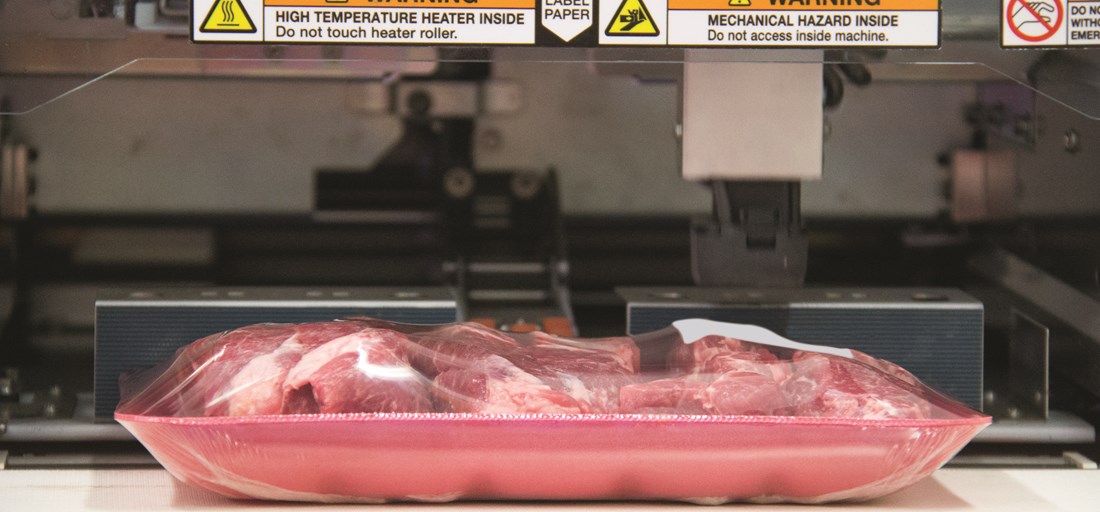

Wrapped Up in Something Big

FeedMore Western New York’s Meals on Wheels program is making a huge impact on food security among local seniors with the help of an Ishida WM-Ai automatic wrapper.

FeedMore Western New York’s (WNY) Meals on Wheels program has dramatically improved efficiency after implementing an Ishida WM-Ai automatic wrapper in their production processes. The road to this solution wasn’t simple, but choosing to work toward eliminating food insecurity and isolation was.

Publish Date: 05/29/2020

Food Security for Seniors

The Meals on Wheels program of Buffalo, New York was founded in 1969 and has been reducing food insecurity by delivering nutritious meals to senior residents in their area ever since. Being “food insecure” means having limited or uncertain access to safe and nutritionally essential foods. According to the USDA, having “very low food security” is indicated by multiple occurrences of disrupted eating patterns and reduced food intake, which may mean missing meals or not having access to enough food to survive. From 2007 to 2014 there was a 65% increase in the number of senior citizens who struggle with hunger and food insecurity. As of 2017, nearly 8 million Americans who are age 65 or older face the threat of food insecurity.

FeedMore WNY partnered with TRIO Community Meals, who they knew would be dedicated to helping distribute safe, reliable meal delivery services. TRIO Community Meals has over 50 years of experience providing nutritionally balanced meals to seniors who are homebound or living in congregate sites, such as senior living centers. Supplying healthy meals and friendship to vulnerable seniors is a passion that inspires every devoted TRIO team member and their partners. Everyone is united by the sincere belief that by working together, senior hunger and isolation can be eliminated.

FeedMore WNY’s Meals on Wheels program provides 4,000 meals every day to senior citizens in Buffalo and 28 surrounding communities. With so many citizens depending on them, FeedMore WNY and TRIO Community Meals continually seek ways to improve meal quality and production efficiency. They also wanted to find a way to reduce the strain of the repetitive wrapping motion on the employees who had been manually wrapping every meal. Stretching the film, filling the trays and carefully wrapping the contents with a neat, secure seal by hand is a time-consuming, exhausting process. Hand-wrapping the meals was an all-day task for four people and often led to sore muscles; they needed a better solution to continue to successfully serve their community.

Rose Ashraf, Operations Director for TRIO Community Meals, researched several different automatic wrappers and said the first automatic wrapper they tried was from a different manufacturer and it didn’t make the cut. They continuously had problems with operations and decided to return that wrapper and reignite the search. She continued researching products and suppliers, seeking an automatic wrapper that would be reliable, easy to use, and consistently produce an attractive seal—with the added benefit of local training and support. After reviewing Ashraf’s research, the TRIO and FeedMore WNY teams decided that the Ishida WM-Ai automatic wrapper was exactly what they were looking for. While this model was available from more than one supplier, what convinced them to choose Rice Lake Weighing Systems was the support they received from their service representative and Rice Lake Retail Solutions distributor, Gregg Barren.

Ashraf says they have been working with Barren, owner of Independent Saw in New York, since they first began considering the WM-Ai automatic wrapper. Barren has been in the industry since 1987 and working with Ishida products since 2006. He took Ashraf to another site that was using a similar Ishida wrapper and allowed her to test it with products used by TRIO Community Meals and FeedMore WNY. She was ecstatic with the neat, presentable seal the wrapper provided for every tray she put through it. The support Barren provides coupled with the affordability of the WM-Ai from Rice Lake Retail Solutions were also key factors in the decision. Ashraf had found the same automatic wrapper from another supplier, who would have charged more and wouldn’t provide the same availability for on-site support.

Gregg Barren worked side-by-side with a Rice Lake representative during the installation of the WM-Ai. During the installation there were a few minor issues concerning where food was being placed on the trays. “He had a couple good suggestions on packaging and placement of their apples and oranges, I mean literally apples and oranges,” Barren explained when describing working with the Rice Lake representative to adjust the WM-Ai tray alignment. Barren added that when it comes to Ishida wrappers, he’s like the Maytag Man: Once they’re installed, he very rarely gets service calls because they are reliable and easy to use. Additionally, Barren provided comprehensive on-site training and visited FeedMore WNY every day for two weeks to ensure their WM-Ai was operating properly. Ashraf added that Barren has also been quick to respond to any needs for the wrapper. This support and teamwork enhanced the quality of the delivered meals, which has also elevated the senior dining experience.

Ashraf was impressed with not only the neat seals, but also the easy use and speed of the automatic wrapper. The Ishida WM-Ai automatic wrapper can wrap up to 35 trays every minute and three variable infeed speed options prevent items from toppling or spilling during wrapping. FeedMore WNY wraps thousands of meals every day and portions each part of the meals before they are wrapped. Pre-portioned meal items could include meatloaf with gravy, mashed potatoes, peas with pearl onions, cottage cheese with fruit, and bread, each packaged in individual containers. The WM-Ai is also easy to clean if there is ever an accidental spill. A film pre-stretching function helps ensure a neat, secure wrap every time. Each container is safely, reliably and appealingly wrapped on its tray, no matter what’s on the menu.

TRIO Community Meals and FeedMore WNY’s Meals on Wheels program began using the WM-Ai in the fall of 2017 and within two years they had wrapped and delivered more than 1 million meals in their community. While it took some getting used to, the WM-Ai users have all agreed they love having it at their facility; Ashraf says their favorite part is that it does what they need it to. Before using the WM-Ai, manually wrapping trays was a day-long process that resulted in slow production in other process areas. After beginning to use the WM-Ai, however, the employees who once spent their days wrapping trays by hand can now support the areas of production responsible for portioning food. Once this prepared food has been portioned and packaged in small containers, it is passed to the wrapping station where it is placed on a tray and quickly wrapped up.

The WM-Ai can easily accommodate different sized trays and food containers for a variety of meal options. Ashraf has also been very happy with the WM-Ai’s dependability. “It’s very reliable, simple to operate and it works like a machine! Which is what it is,” she laughed as she explained Meals on Wheels WNY’s success with the wrapper.

With FeedMore WNY’s Meals on Wheels program providing six different meal options for a variety of dietary and health needs, the WM-Ai will certainly stay busy. Thanks to Gregg Barren at Independent Saw and the Ishida WM-Ai, FeedMore WNY and TRIO Community Meals are able to efficiently and reliably battle food insecurity in Western New York.

Learn more about the WM-Ai automatic wrapper.

Subscribe to Rice Lake Magazine

Sign in or create a Rice Lake website account to request a Rice Lake Magazine filled with application stories like this one be sent to you.

Account Sign In Create an Account

My Account

My Account