Is the website displaying in the correct language? Please confirm or select a different language.

Your region has been set automatically. Please confirm or select a different region.

An intelligent, self-diagnostic scale system that

identifies problems before they result in downtime.

VIRTUlink constantly monitors the health and performance of connected scales.

By integrating with the iQUBE²® digital diagnostic junction box and connecting weighing equipment to the

cloud, VIRTUlink enables remote diagnostics, automates alerts and secure access for troubleshooting.

How VIRTUlink helped optimize production and uptime

for TriRX Pharmaceutical Services

As a quickly growing company, TriRX Pharmaceutical Services relies on the best equipment to maintain reliability in the highly regulated pharmaceutical industry. To improve their production environment and overall responsive capabilities, TriRX implemented VIRTUlink™ into their everyday processes.

VIRTUlink constantly monitors the health and performance of connected equipment. After the system notified operators of a tank scale's erratic readings, they remotely accessed alert logs and identified a damaged cable. Quickly replacing the cable maintained product quality before it was negatively impacted.

“We saw an opportunity to leverage VIRTUlink on our 1,000-, 2,000- and 5,000-gallon tanks to see how our load cells were performing in real-time. It turned out to be a game-changer that helped all groups involved.”

Christy Pinkerton, project engineer,

TriRx Pharmaceutical Services, LLC.

VIRTUlink systems connect up to four iQUBE2 digital junction boxes per gateway, accommodating up to 16 scales. Consult Rice Lake's integration specialists to determine hardware needs and to discuss network requirements.

Safely Monitor & Analyze Scale Data

Secure

Data Storage

Data encryption, signed software and physical

separation of networks protects against security

breaches. Cloud data is hosted on AWS for

state-of-the-art electronic security.

Automated

Alerts

Scale conditions are constantly monitored

to evaluate system health. If an issue is detected,

VIRTUlink displays an alert and automatically sends

a message to designated users.

Web

Dashboard

VIRTUlink's online portal provides secure,

remote access to process status in real-time.

Identify service needs, review technician notes

and configure the home screen to display the

most critical information.

Load Cell

Emulation

If a weighing problem reaches critical levels,

continue using the scale by enabling load cell emulation.

By comparing load cells with intelligently calculated

values, emulation can keep a scale operational

until repairs can be made.

Works With New

& Existing Applications

VIRTUlink is compatible with most applications

using analog load cells, and can be easily added

to installations already using an iQUBE2

digital junction box.

Expandable Functionality

VIRTUlink is expandable with support

for multiple datapoints from weight indicators,

junction boxes, auxiliary equipment, sensors

and web relays, and IP cameras.

Optimize Uptime with Data Insight

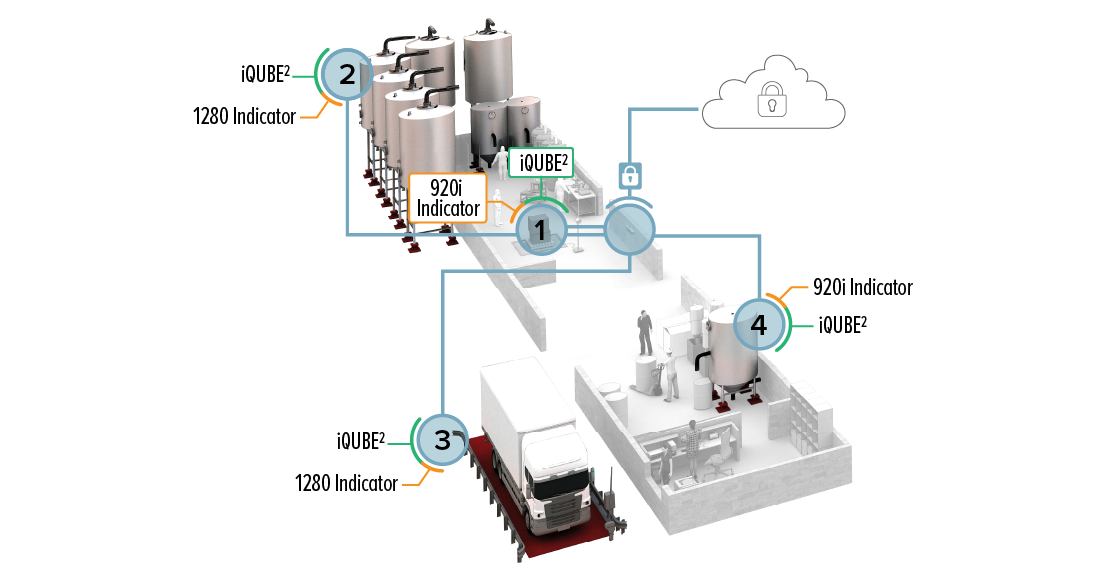

Essential for critical applications where scale downtime results in lost profit, decreased product quality, unnecessary waste or opportunity cost, VIRTUlink intelligently monitors and analyzes weighing systems across entire processes. From shipping and receiving to inventory, safety and quality control, VIRTUlink helps ensure your business keeps moving forward.

Scale conditions are constantly evaluated for errors including underload/overload, drift, loss of connection, noise or instability, return-to-zero failure and out of balance. By identifying these issues, uptime can be optimized through the power of VIRTUlink's web dashboard and automated alerts.

1. Shipping and Receiving

Floor Scale, iQUBE2 and 920i Indicator

For warehouses with real-time inventory data and/or product traceability, monitoring floor scale health ensures this busy environment keeps running smoothly.

3. Incoming/Outgoing Transactions

Truck Scale, iQUBE2 and 1280 Indicator

A truck scale often operates as a company's cash register. As products enter or leave the facility, invoices are created based on recorded weight. VIRTUlink can immediately notify operators and key personnel of potential issues.

2. Recipe Batching

Weigh Modules, iQUBE2 and 1280 Indicator

Automated product manufacturing through weight-based batching increases efficiency and maintains product consistency. With VIRTUlink continually monitoring this process, valuable insights into operations are available 24/7/365. The system's configurable, automated alerts help ensure potential issues are identified and can be corrected before resulting in errors and waste.

4. Quality Control

Weigh Modules, iQUBE2 and 920i Indicator

Inconsistent quality can result in lost business, decreased safety and diminished confidence. VIRTUlink serves as a constant and efficient tool to maintain quality through the highest standards of accuracy, without sacrificing speed.

System Components

My Account

My Account